In recent years, the CE marks are more and more widely used in the market of European economic area (Member states of the European Union and the European Free Trade association, except Switzerland). More customs of different countries set out the requirements of CE certification for imported products. Exporter will be in trouble as well as unnecessary loss if their shipping goods don’t have CE certified label. So, what is the importance of CE certification? What are the forms of CE certification so far? And what are the risks of products that has not been certified by CE?

1. The importance of CE certification

The CE mark on the packaging indicates that it meets the requirements of a series of European directives such as safety, sanitation, environmental protection and consumer protection. In the past, EC(European Community)countries require differently for import and sale of products. The goods which are produced according to national standards may not be on the market. As part of the efforts to eliminate trade barriers, CE came into being at that time. Therefore, CE can be understood as CONFORMITY WITH EUROPEAN (DEMAND) (in Europe).

The meaning of the CE mark is as the following: Using CE acronym as symbol shows products which affix the CE mark meet the main requirements of relevant provisions of the European Directive (Essential Requirements),and it’s also used to verify that the products have passed the conformity assessment procedure or the manufacturer’s declaration of conformity. The CE mark is truly as a passport for the products being allowed to enter the European market. For industrial products which must affix CE mark according to relevant instructions, they can be in the market without CE mark, or they must be taken back if they don’t meet safety requirements but with CE mark and in the market. For industrial products which must affix CE mark according to relevant instructions, they can be in the market without CE mark, or they must be taken back if they don’t meet safety requirements but with CE mark and in the market. Moreover, the products will be restricted and prohibited from entering the EU market or forced to withdraw from the market if they violate CE mark instructions in European Directive.

The most important function of CE is to ensure the safety of the products and ensure the products work well under the conditions of the European union. CE mark like a tickets for products entering the European market, if products are not certified by CE, it’s most likely to be seized of by European customs and cause exporters’ unnecessary losses.

2. Advantages of CE certification

The import of CE certified electronic instruments and equipment can effectively avoid the following risks:

The risk of being detained and investigated by the customs;

The risk of being investigated and dealt with by the market supervision institution;

The risk of being charged by competitor for other purpose;

The import of CE certified electronic instruments and equipment has the following advantages:

The import of CE certified equipment can avoid a lot of trouble in the import and export because the laws, regulations as well as standards of EU are not only numerous, but also very complex;

It can enhance the reliability of their product performance by using CE certified equipment for testing or production. It also can effectively prevent the emergence of irresponsible allegations;

The CE certificate of the institution designated by European Union will be the important evidence with legal effect when you are facing to litigation;

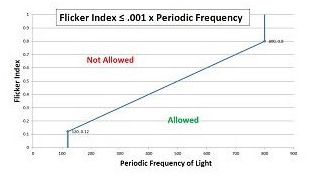

For electronic equipment and testing equipment, there is a very important parameter ” EMC test” when the products are doing CE certification. Because the power grid frequency, voltage in Europe countries are differen from China Mainland, these products are likely to be damaged in the course of use if not detected. At the same time, there are many interference factors such as pulse group, lightning surge interference, voltage dip and so on. If there is no CE certification, the equipment is likely to be damaged and can’t be used normally.

3. Current forms of CE certification in China mainland

At present, there are three kinds of domestic CE certification as following:

A:Only certified certificate, no test report:

This type of certificate is almost invalid and cannot be queried on the appropriate website. Products with this certification mark can’t be recognized as ticket to the European market. Products with this kind of certificate is equivalent to the product without CE mark, and they should be detained or even returned.

B: Certificate of compliance / Certificate of compliance, with test report:

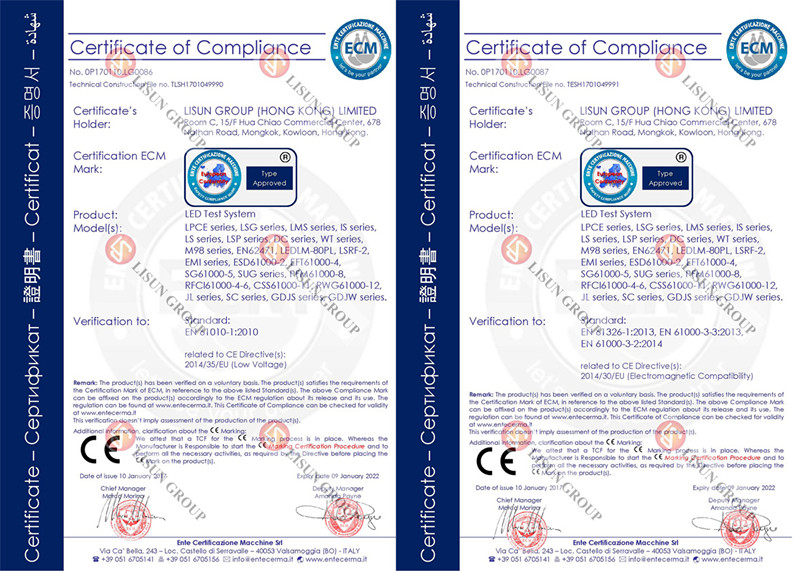

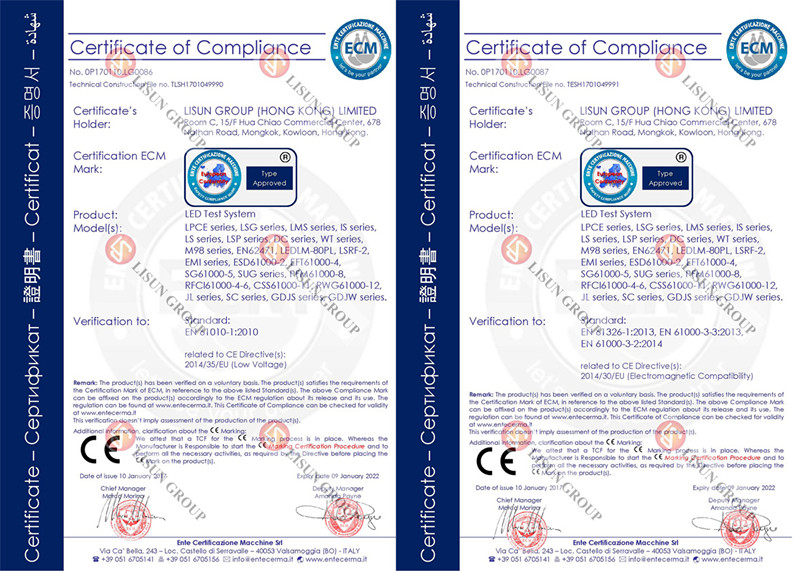

This type of certificate is issued as a statement of conformity by the third party Agency (agency or test certification body). The test reports and other technical documents TCF should be enclosed by this kind of certificate. At the same time, enterprises also have to sign the<declaration of conformity>. This type of certification report is only recognized in mainland China. Although there are the test report and related certificates according to the requirement, the relevant information can only be checked on the detection of the company’s own website. But many such testing company themself do not comply with EU certification requirements. The certificate is only applicable to the manufacturer for product quality self inspection, there is also a greater risk of being detained by the customs ana cause fines and delivery delays. This will affect the normal use of products. This kind f certificate is shown in the following figure :

C: EC Attestation of conformity < EU standard compliance certificate >

This type of certificate is issued by the EU notified body (Notified Body known as NB). According to EU regulations, only the NB are eligible to issue EC Type CE Declaration.

This type of certificate and test report are issued by testing organization certified by EU. The products finish the complete testing during the certification process and has a complete test report. Meanwhile, certificate No. can be found in the appropriate Website. Only these electronic equipment which has finished the testing and certification can be exported to EU and can get CE label. All of Lisun series devices do CE certification in such bodies certified by European Union, and has integrated <EU standard compliance certificate> and corresponding test report. Certificate template is shown in the following figure:

Lisun is lead in designing and producing high quality, high precision, high performance products to Europe and customers from all over the world. Lisun applied the first CE certification at the beginning of entering the European market and provide long-term excellent quality services for European customers. When the CE certificate expires, Lisun immediately contact the top certification bodies to do.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are

Goniophotometer,

Spectroradiometer,

Integrating Sphere,

LED Test Instruments,

CFL Test Instruments,

Photometer and Colorimeter,

EMC & EMI Testing,

Surge Generator,

Electrical Safety Testing,

Environmental Test Chamber, IP

Waterproof Test Equipment,

Dustproof Test Chamber,

High and Low temperature Humidity Chamber,

Plug and Switch Testing,

AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep:

Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep:

Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

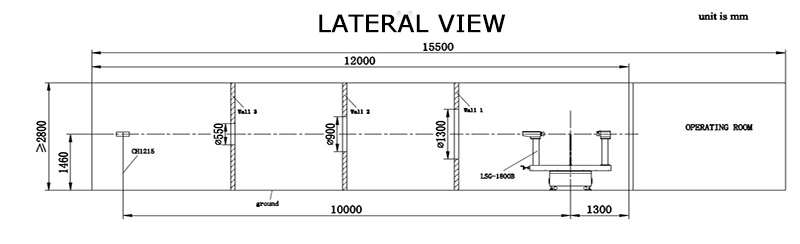

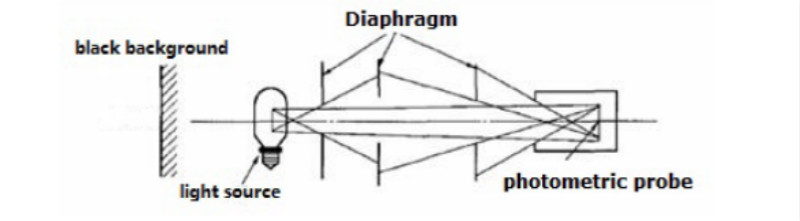

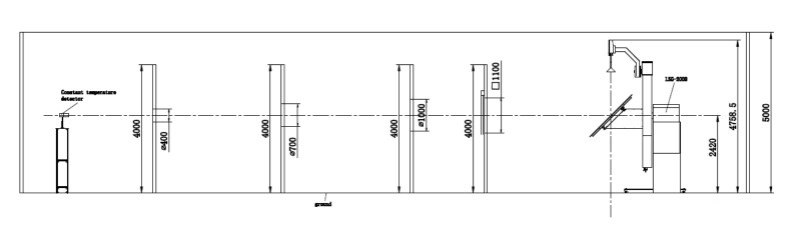

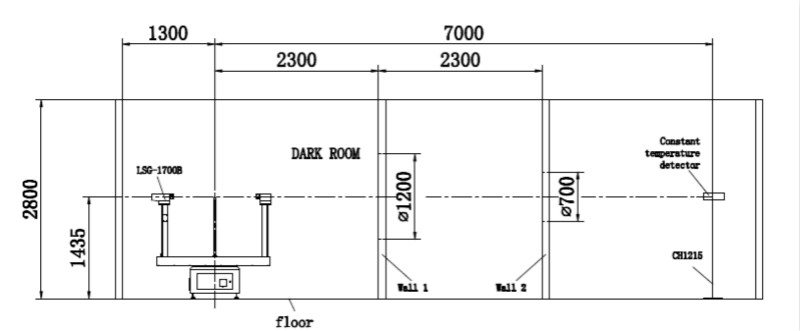

LSG-1700B High Precision Rotation Luminaire Goniophotometer

LSG-1700B High Precision Rotation Luminaire Goniophotometer