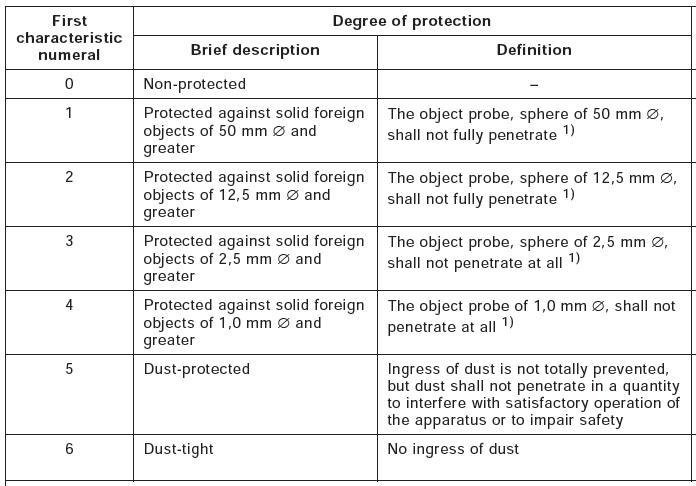

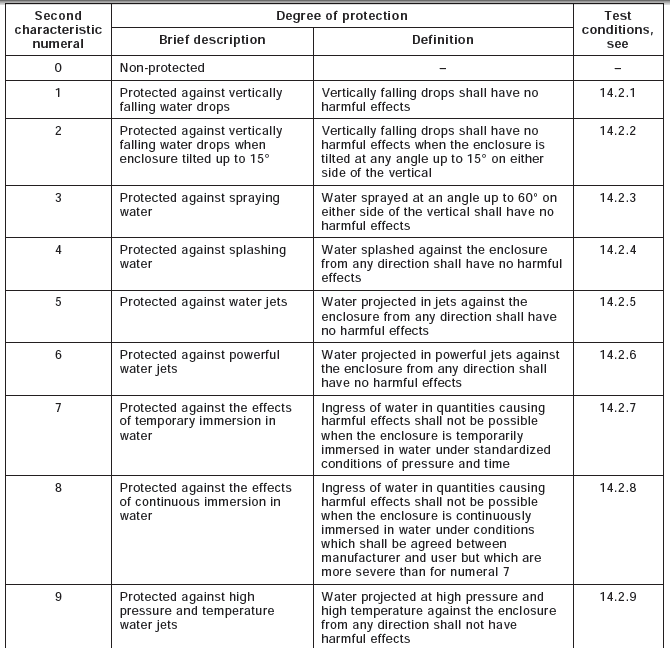

Waterproof grade reflects the ability of moisture-proof of products. Especially for outdoor activities, it is unavoidable to be in the harsh environment of high humidity. The sealing and water-proof ability of the instrument is very important to ensure the safe of operation and life of the instrument.

At present, there are many manufacturers producing waterproofing equipment on the market. What are the advantages of LISUN

waterproof equipment compared with other manufacturers? There are some advantages for LISUN waterproof in below:

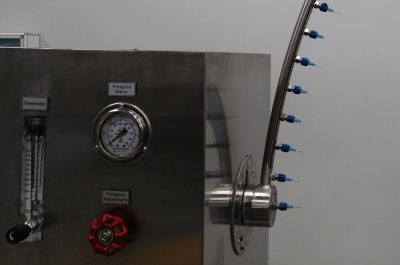

1. On the side of excellent cost performance, In test equipment market, the quality of LISUN waterproof equipment is good than the waterproof equipment of most of suppliers. Please kindly see Figure 1 and Figure 2. Besides, the price of LISUN waterproof test equipment is very competitive in market. Right price with good quality is cost-effective products for our customer to make a good choice for test equipment. Compare to Figure 2, visibly, the surface of material of LISUN waterproof equipment in Figure 1 (LISUN Model:JL-34) has high gloss. And the surface of material in Figure 2 (Other supplier’s Model) have poor gloss. Good material with high gloss makes the equipment more beautiful visually. Regarding to choosing material, LISUN use SUS304 stainless steel as raw material. One more, the regulator in Figure 1 (LISUN Model JL-34) is much better than the regulator in Figure 2.

Figure 1: Surface of IPX3-IPX4 (LISUN Model:JL-34)

Figure 2: Surface of IPX3-IPX4 (Other supplier's model)

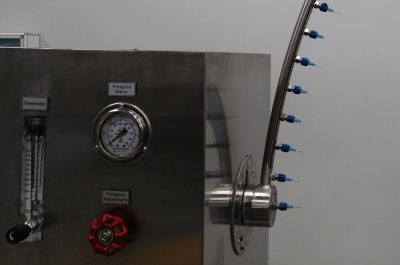

2. Speaking of structure of IPX3-IPX4, please kindly see Figure 3 and Figure 4 in below. The waterproof test equipment in Figure 4 (Other supplier’s Model) is Wall-Hanging Split Type, but the waterproof test equipment in Figure 3 (LISUN Mode: JL-34) is Two Cabinets Type. Compare to Wall-Hanging Split Type, two cabinets type is easy to carry. Besides, the cabinets of LISUN model JL-34can be mounted wheels at the bottom, which is more easier for operator to carry and adjust placement.

Figure 3: Two Cabinets Type IPX3-IPX4 test equipment (LISUN Model:JL-34)

Figure 4: Wall-Hanging Split Type IPX3-IPX4 test equipment (Other supplier’s Model)

3. With the view of production details for waterproof test equipment, we can see many welded junctions in Figure 6 and Figure 7(Other supplier’s Model), which not only affects appearance, but also makes it easier for water to erode equipment. please kindly see Figure 5 & Figure 6 & Figure 7 in below. In Figure 5(LISUN Model: JL-34), we can see that the surface of the equipment is clean and glossy, and there is no welded junction.

Figure 5: Production details (LISUN Model:JL-34)

Figure 6: Production details (Other supplier’s Model)

Figure 7: Production details (Other supplier’s Model)

4. Speaking of turntable, we can easily judge the good or bad quality of turntable by through below Figure 8 and Figure 9. After waterproof test equipment is used for a long time, in below Figure 9 (Other supplier’s Model), we can find many rust spots on the machine. In below Figure 8(LISUN Model:JL-34), there is no rust spot on that machine. Thus it can be seen good material can make machine have good corrosion resistance and durability. The turntable of LISUN model JL-34 also mounted wheels at the bottom. This is also more convenient for the operator to move the turntable.

Figure 8: Turntable of IPX3-IPX4 (LISUN Model:JL-34)

Figure 9: Turntable of IPX3-IPX4 (Other supplier’s Model)

5. For swing pipe and spray nozzle for IPX3 and IPX4, compare to Figure 11, the quality of swing pipe and spray nozzle in Figure 10 is better and more elaborate .which also make operator control water flow accurately, and Good parts can make the equipment be used for long term.

Figure 10: IPX3-IPX4 Swing pipe and spray nozzle (LISUN Model:JL-34)

Figure 11: IPX3-IPX4 Swing pipe and spray nozzle (Other supplier’s Model)

6. Regarding to wire of waterproof, please kindly see Figure 12 and Figure 13 in below. Wire is exposing outside of equipment in Figure 13 (Other supplier’s Model). If operator use the machine for a long time in damp environment, that will be easy to make safety issue. So such design for waterproof equipment is not safe for operator. In Figure 12 (LISUN Model:

JL-34), Wires are wrapped in plastic pipes, in that way, it can protect operator when operator use equipment. From a safety point of view, LISUN Model is also much better.

Figure 12: Wire of IPX3-IPX4 (LISUN Model:JL-34)

Figure 13: Wire of IPX3-IPX4 (Other supplier’s Model)

In all, before purchasing waterproof test equipment, please consider from different sides. Through the above comparisons, we believe that LISUN waterproof test equipment will be your best choice.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are

Goniophotometer,

Spectroradiometer,

Integrating Sphere,

LED Test Instruments,

CFL Test Instruments,

Photometer and Colorimeter,

EMC & EMI Testing,

Surge Generator,

Electrical Safety Testing,

Environmental Test Chamber,

Waterproof Test ,

Dustproof Test Chamber,

High and Low temperature Humidity Chamber,

Plug and Switch Testing,

AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep:

Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep:

Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

SC 015_Dustproof Testing Machine

SC 015_Dustproof Testing Machine

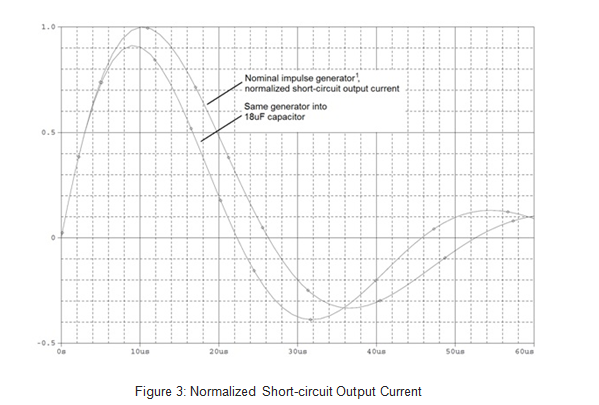

What’s new: IEC 61000-4-5 Second Edition vs. Third Edition

What’s new: IEC 61000-4-5 Second Edition vs. Third Edition

What’s new: IEC 61000-4-5 Second Edition vs. Third Edition

What’s new: IEC 61000-4-5 Second Edition vs. Third Edition

SG61000-5_Surge Generator

SG61000-5_Surge Generator