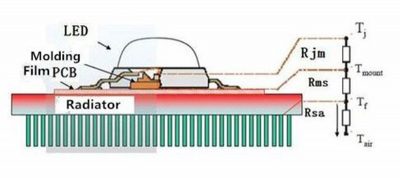

LED package is mainly to provide a platform for LED chips, so that LED chips have better performance of light, electricity and heat. Good packaging can make LEDs have better luminous efficiency and good heat dissipation environment, and good heat dissipation environment can enhance LEDs. The service life. LED packaging technology is mainly built on five main considerations, namely optical extraction efficiency, thermal resistance, power dissipation, reliability and cost performance (Lm/$).

There are many kinds of LED chip packages, and different styles of packages should be used according to the actual photoelectric characteristics. However, the common LED packages have the following five common patterns.

First, the LED chip soft package, this package style is generally used in the LED display of character display, digital display, and electric display. The soft package of the LED chip is to directly bond the LED chip on the PCB printing plate, and connect the desired characters and display effects through the welding wire. These chips and wire bonds are then protected with a transparent resin.

Second, the pin packing method. The main advantage of this kind of package is that it can flexibly control the angle of light emitted by the LED chip, and it can also easily realize the function of measuring light. The pin package method only needs to fix the chip on the lead frame and then encapsulate it with epoxy resin. Can be a single LED device.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Thursday, February 27, 2020

LED Lamps Aging and Life Test

Many customers need aging LED lamps, but do not have a clear concept of aging test and life test.

Aging test usually use aging test racks. What is aging test rack? Aging rack is dedicated to simulate the products in real conditions involved in the use of various factors on the aging of the product conditions to strengthen the process of the corresponding conditions.

Why we need aging test? Electronic products, no matter components, parts or machines, all need aging test. Aging and test is not one concept, aging firstly and then test. Electronic product after manufacturing forms a complete product, which is able to play its role. But users may find a variety of problems after use, most problems occurs in the first few hours to dozens of hours. Later, formulate electronic products aging and test to simulate the using state or equivalent products. This process is done by the product manufacturer.

The problem products will stay in factory, products without problems will sell to users, to ensure that the products that users buy are reliable or less problematic, which is the meaning of aging test.

LED life and reliability of LED products is one of the most important performances. Life is the ultimate performance of reliability, but the theoretical life of LED is very long, according to the use of different conditions and drive current, LED life has 50.000 hours or more. Different with the traditional light source, LED will not go out instantly, but decays slowly. According to LM-80, LED light source should operate at the lowest temperature of the three case temperatures (Ts) for the photometric test and should use the same drive current. These three case temperatures should be 55℃, 85℃ and a third temperature provided by the DUT manufacturer. The case temperature provided by the DUT manufacturer and drive current should meet the customers’ requirements and are within the recommended operating temperature range. Test unit should be driven for at least 6000 hours and the data collected at least every 1000 hours.

Rated Lumen Maintenance Life is the elapsed operating time over which the LED light source will maintain the percentage of its initial light output. The lumen maintenance rate is a contradiction of the flux attenuation.

Lisun LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to standards of IES-LM-80, IES-LM-82, TM-21 and GB2312-80.

Aging test usually use aging test racks. What is aging test rack? Aging rack is dedicated to simulate the products in real conditions involved in the use of various factors on the aging of the product conditions to strengthen the process of the corresponding conditions.

Why we need aging test? Electronic products, no matter components, parts or machines, all need aging test. Aging and test is not one concept, aging firstly and then test. Electronic product after manufacturing forms a complete product, which is able to play its role. But users may find a variety of problems after use, most problems occurs in the first few hours to dozens of hours. Later, formulate electronic products aging and test to simulate the using state or equivalent products. This process is done by the product manufacturer.

The problem products will stay in factory, products without problems will sell to users, to ensure that the products that users buy are reliable or less problematic, which is the meaning of aging test.

LED life and reliability of LED products is one of the most important performances. Life is the ultimate performance of reliability, but the theoretical life of LED is very long, according to the use of different conditions and drive current, LED life has 50.000 hours or more. Different with the traditional light source, LED will not go out instantly, but decays slowly. According to LM-80, LED light source should operate at the lowest temperature of the three case temperatures (Ts) for the photometric test and should use the same drive current. These three case temperatures should be 55℃, 85℃ and a third temperature provided by the DUT manufacturer. The case temperature provided by the DUT manufacturer and drive current should meet the customers’ requirements and are within the recommended operating temperature range. Test unit should be driven for at least 6000 hours and the data collected at least every 1000 hours.

Rated Lumen Maintenance Life is the elapsed operating time over which the LED light source will maintain the percentage of its initial light output. The lumen maintenance rate is a contradiction of the flux attenuation.

Lisun LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to standards of IES-LM-80, IES-LM-82, TM-21 and GB2312-80.

Wednesday, February 26, 2020

ISO 17025: Accreditation Criteria for the Competence of Testing and Calibration Laboratories

ISO 17025 is the international standard for laboratory accreditation services; the latest version is released in May, 2005. The full name of ISO/IEC 17025:2005-5-15 is Accreditation Criteria for the Competence of Testing and Calibration Laboratories. ISO17025 standard is the laboratory management standard formulated by the international Standardization Organization ISO/CASCO (Conformity Assessment Committee). Internationally the organization that manages laboratory accreditation is International Laboratory Accreditation Cooperation (ILAC), attended by 44 laboratory accreditation institute including CHINA NATIONAL ACCREDITATION COMMITTEE FOR LABORATORIES (CNACL).

Standard mainly includes: definitions, organization and management, quality system, audits and reviews, personnel, accommodation and environmental conditions, equipment and reference materials, traceability and calibration, calibration and test methods, sample management, record, certificate and report, subcontracting tests and calibrations, purchasing services and suppliers, complaints etc. This standard core content is equipment and reference materials, traceability and calibration, calibration and test methods and sample management; these contact emphasis is to assess whether the laboratory or test capability meets the expected requirements.

CHINA NATIONAL ACCREDITATION SERVICE FOR CONFORMITY ASSESSMENT (CNAS) laboratory accreditation criteria are according to ISO/IEC 17025, it is an internationally accepted standard for laboratory quality and technical requirements. The laboratory gets accredited by CNAS, which means that it has been established a set of quality management system based on international standards. As long as the personnel carry out work according to the system strictly, the laboratory’s technical capacity will be guaranteed. The test/calibration services provided by the laboratory to the customer can claim to be accordance with the international standards.

CNAS is the only laboratory accreditation institute in China; it bears nationwide laboratories for ISO17025 standard approval. All calibration and test laboratories can adopt and implement the ISO 17025 standard. In accordance with international practice, data provided by the ISO17025 standard laboratory have legal effect and get international recognized. At present, China has more than 1,000 laboratories that get through the ISO17025 standard certification. Through the implementation of standard to improve the accuracy of the test data and results and expand the laboratory’s reputation, thereby greatly improve the economic and social benefits.

All Lisun products can be sent to CNAS laboratory to do calibration and get CNAS calibration certificate, which meets ISO17025 standard.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Standard mainly includes: definitions, organization and management, quality system, audits and reviews, personnel, accommodation and environmental conditions, equipment and reference materials, traceability and calibration, calibration and test methods, sample management, record, certificate and report, subcontracting tests and calibrations, purchasing services and suppliers, complaints etc. This standard core content is equipment and reference materials, traceability and calibration, calibration and test methods and sample management; these contact emphasis is to assess whether the laboratory or test capability meets the expected requirements.

CHINA NATIONAL ACCREDITATION SERVICE FOR CONFORMITY ASSESSMENT (CNAS) laboratory accreditation criteria are according to ISO/IEC 17025, it is an internationally accepted standard for laboratory quality and technical requirements. The laboratory gets accredited by CNAS, which means that it has been established a set of quality management system based on international standards. As long as the personnel carry out work according to the system strictly, the laboratory’s technical capacity will be guaranteed. The test/calibration services provided by the laboratory to the customer can claim to be accordance with the international standards.

CNAS is the only laboratory accreditation institute in China; it bears nationwide laboratories for ISO17025 standard approval. All calibration and test laboratories can adopt and implement the ISO 17025 standard. In accordance with international practice, data provided by the ISO17025 standard laboratory have legal effect and get international recognized. At present, China has more than 1,000 laboratories that get through the ISO17025 standard certification. Through the implementation of standard to improve the accuracy of the test data and results and expand the laboratory’s reputation, thereby greatly improve the economic and social benefits.

All Lisun products can be sent to CNAS laboratory to do calibration and get CNAS calibration certificate, which meets ISO17025 standard.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

IP Level Test Introduction

IP is the abbreviation of Ingress Protection. IP grade is the protection level for electrical equipment shell against the foreign body intrusion. It comes from the international electrical commission standard IEC 60529 which was also used as the national

standard of America in 2004. In this standard, for the protection level of electrical equipment shell against the foreign body intrusion, the IP level format is IPXX. In which the XX are the two Arabia number. The first tag number indicates the protection level of contact protection and external object protection; the second tag number indicates the protection level of waterproof. For the more specific protection level can refer to the table below.

Level of protection usually uses IP with the following two figures to express. The numbers used to specify the protection level. The first number indicates the range of the device against dust, or the extent of people against damage in sealed environment. ‘ I ‘ represents the level of prevention of the entry of solid foreign bodies, and the highest level is 6; the second number indicates the level of the device against water. P representative the level prevent from water, the highest level is 8. Such as the protection level of motor IP65, IP55 and so on.

Dustproof Level

Waterproof Level

(1) IPX 1

Method name: Vertical drop test

Test equipment: Drop test device

Sample placement: According to the normal working position of the sample, place the sample on the rotating sample table of 1r/min. The distance between the top of the sample and the drop mouth is no more than 200mm

Test condition: Drip rate is 10.05 mm/min

Duration: 10 min

(2) IPX 2

Method name: Inclined 15 degree drop test

Test equipment: Drop test device

Sample placement: Making a 15° angle between the sample surface and the vertical line. The distance between sample top to drip mouth no greater than 200mm. After each test, change to the other side, a total of four times.

Test condition: Drip volume is 30.5 mm/min

Duration: 4 x 2.5 min (total 10 min)

(3) IPX 3

Method name: water spray test

Test method:

Sample placement: Select the appropriate radius of the tube so that the sample table height is in the position of the diameter of the pipe diameter. Place the sample on the sample table to make the distance between the top of the sample is no more than 200mm, and the sample table is not rotated.

Experimental conditions: Water volume calculated according to the number of holes in the pipe, each hole is 0.07 L/min. When pouring water, the spray hole which placed in the both sides of the swing pipe would spray to the sample. The sample placed in the pipe center circle. The swing pipe would swing 60° twice on both sides of the vertical of 60 degrees, total 120°. Each swing (2 x 120) is about 4s

Test time: Continuous pouring water 10 min

Sample placement: Make the parallel distance between the top of the test and the head of the hand-held nozzle is 300mm to 500mm

Test condition: When the test should be installed with the balance of the baffle, the water flow is 10 L/min

Test time: According to the sample shell surface area calculated, per square meter is 1 min (not including the installation area), at least 5 min

(4) IPX 4

Name: splashing test method

Test method:

Test conditions: In addition to the conditions following, all the same and the above IPX 3 a models are the same; the water spray area is placed in the middle of the tube at the same time, the 90 degrees of the water spray nozzle. The sample is placed in the pipe center circle. The vertical pipe swing of 180° on both sides, total about 360 degrees. Each swing (2 x 360) is about 12s

Test time: Same as the above IPX 3 a models(that is, 10 min).

Test conditions: Installation of the device on the installation of a balanced weight of the baffle, and the rest of the above IPX 3 b;

Test time: Same as the above IPX 3 b models, that is, the sample of the shell surface area per square meter is 1 min (not including the installation area) at least 5min

(5) IPX 5

Method name: Spray test

Test equipment: The nozzle diameter of the nozzle is 6.3mm

Test condition: The water flow rate is 2.5m (750 L/min), the water flow rate is 12.5 3M (L/h).

Test time: According to the sample shell surface area calculation, per square meter is 1 min (not including the installation area) at least 3 min

(6) IPX 6

Method name: Strong water spray test;

Test equipment: Nozzle diameter of 12.5 mm

Test conditions: 100 L/min (6000 L/h)

Test time: According to the sample shell surface area calculation, per square meter is 1 min (not including the installation area) at least 3 min

(7) IPX 7

Method name: Short-time immersion test

Test equipment and test conditions: Immersion tank. The sample size should be put into the immersion tank, and the distance between the bottom of the sample and the surface of the sample is at least 1m. The top of the sample is at least 0.15m

Test time: 30 min

(8) IPX 8

Method name: continuous dive test;

Test equipment, test conditions and test time: Decided by the supply and demand (sell and buy). Its severity degree is higher than IPX 7.

Note: In addition, many outdoor electronic products also stress the ability to float.

Lisun developed JL-X waterproof test system and SC series of dust test box fully meet the IEC 60529. Lisun Electronic (Shanghai) office is committed to the development and after-sales maintenance of lighting instrument, EMI / EMC testing system and safety testing instruments in the domestic and global market. The full range of products of Lisun are in strict accordance with the quality management and control of ISO9001:2008 requirements for R & D and production; Lisun is also the member unit of global lighting CIE association, all products are according to CIE requirements; in addition, all products of Lisun are certified by CE and get the qualification of the EU.

standard of America in 2004. In this standard, for the protection level of electrical equipment shell against the foreign body intrusion, the IP level format is IPXX. In which the XX are the two Arabia number. The first tag number indicates the protection level of contact protection and external object protection; the second tag number indicates the protection level of waterproof. For the more specific protection level can refer to the table below.

Level of protection usually uses IP with the following two figures to express. The numbers used to specify the protection level. The first number indicates the range of the device against dust, or the extent of people against damage in sealed environment. ‘ I ‘ represents the level of prevention of the entry of solid foreign bodies, and the highest level is 6; the second number indicates the level of the device against water. P representative the level prevent from water, the highest level is 8. Such as the protection level of motor IP65, IP55 and so on.

Dustproof Level

| Number | Protection Level | Definition |

| 0 | No protection | No special protection |

| 1 | Prevent objects from more than 50mm | Prevent the human body from accidentally touch the internal parts of the lamp, prevent the object intrusion which diameter is greater than 50mm |

| 2 |

Prevent objects from more than 12mm | Prevent the finger from the internal parts of the lamp |

| 3 | Prevent objects from more than 2.5mm | Prevent the object, tool, wire intrusion which diameter is greater than 2.5mm |

| 4 |

Prevent objects from more than 1.0mm | Prevent the mosquitoes, insects or objects intrusion which diameter of more than 1.0mm |

| 5 |

Dustproof |

Can not completely prevent dust intrusion, but the amount of intrusion of dust will not affect the normal operation of electrical |

| 6 | Dustproof | Completely prevent dust intrusion |

| Number | Protection Level | Definition |

| 0 | No protection | No special protection |

| 1 | Prevent water dripping | Prevent vertical drop of water |

| 2 | Prevent dripping water intrusion even when inclined 15 degrees | Can still prevent dripping when the lamp is inclined 15 degrees, |

| 3 | Prevent the injection of water intrusion | Prevent rain, or vertical to the angle is less than 50 degrees in the direction of the water jet |

| 4 |

Prevent splashing water intrusion | Prevent water from splashing in all directions |

| 5 |

Prevent the ingress of water waves | Prevent the waves or spray holes rapidly sprayed water from intrusion |

| 6 |

Prevent the ingress of water waves |

Lamps and lanterns can still ensure the normal operation when into the water in a certain time or water pressure conditions, |

| 7 |

Prevent water from immersing into the lamp | The lamp has no time limit for the submerged water under the condition of a certain water pressure, and can ensure the normal operation |

| 8 | Prevent the sinking | Prevent the sinking |

(1) IPX 1

Method name: Vertical drop test

Test equipment: Drop test device

Sample placement: According to the normal working position of the sample, place the sample on the rotating sample table of 1r/min. The distance between the top of the sample and the drop mouth is no more than 200mm

Test condition: Drip rate is 10.05 mm/min

Duration: 10 min

(2) IPX 2

Method name: Inclined 15 degree drop test

Test equipment: Drop test device

Sample placement: Making a 15° angle between the sample surface and the vertical line. The distance between sample top to drip mouth no greater than 200mm. After each test, change to the other side, a total of four times.

Test condition: Drip volume is 30.5 mm/min

Duration: 4 x 2.5 min (total 10 min)

(3) IPX 3

Method name: water spray test

Test method:

- Swing Tube type spray test

Sample placement: Select the appropriate radius of the tube so that the sample table height is in the position of the diameter of the pipe diameter. Place the sample on the sample table to make the distance between the top of the sample is no more than 200mm, and the sample table is not rotated.

Experimental conditions: Water volume calculated according to the number of holes in the pipe, each hole is 0.07 L/min. When pouring water, the spray hole which placed in the both sides of the swing pipe would spray to the sample. The sample placed in the pipe center circle. The swing pipe would swing 60° twice on both sides of the vertical of 60 degrees, total 120°. Each swing (2 x 120) is about 4s

Test time: Continuous pouring water 10 min

- Shower nozzle type shower water test

Sample placement: Make the parallel distance between the top of the test and the head of the hand-held nozzle is 300mm to 500mm

Test condition: When the test should be installed with the balance of the baffle, the water flow is 10 L/min

Test time: According to the sample shell surface area calculated, per square meter is 1 min (not including the installation area), at least 5 min

(4) IPX 4

Name: splashing test method

Test method:

- Swing pipe type splashing test

Test conditions: In addition to the conditions following, all the same and the above IPX 3 a models are the same; the water spray area is placed in the middle of the tube at the same time, the 90 degrees of the water spray nozzle. The sample is placed in the pipe center circle. The vertical pipe swing of 180° on both sides, total about 360 degrees. Each swing (2 x 360) is about 12s

Test time: Same as the above IPX 3 a models(that is, 10 min).

- Nozzle type splashing test

Test conditions: Installation of the device on the installation of a balanced weight of the baffle, and the rest of the above IPX 3 b;

Test time: Same as the above IPX 3 b models, that is, the sample of the shell surface area per square meter is 1 min (not including the installation area) at least 5min

(5) IPX 5

Method name: Spray test

Test equipment: The nozzle diameter of the nozzle is 6.3mm

Test condition: The water flow rate is 2.5m (750 L/min), the water flow rate is 12.5 3M (L/h).

Test time: According to the sample shell surface area calculation, per square meter is 1 min (not including the installation area) at least 3 min

(6) IPX 6

Method name: Strong water spray test;

Test equipment: Nozzle diameter of 12.5 mm

Test conditions: 100 L/min (6000 L/h)

Test time: According to the sample shell surface area calculation, per square meter is 1 min (not including the installation area) at least 3 min

(7) IPX 7

Method name: Short-time immersion test

Test equipment and test conditions: Immersion tank. The sample size should be put into the immersion tank, and the distance between the bottom of the sample and the surface of the sample is at least 1m. The top of the sample is at least 0.15m

Test time: 30 min

(8) IPX 8

Method name: continuous dive test;

Test equipment, test conditions and test time: Decided by the supply and demand (sell and buy). Its severity degree is higher than IPX 7.

Note: In addition, many outdoor electronic products also stress the ability to float.

Lisun developed JL-X waterproof test system and SC series of dust test box fully meet the IEC 60529. Lisun Electronic (Shanghai) office is committed to the development and after-sales maintenance of lighting instrument, EMI / EMC testing system and safety testing instruments in the domestic and global market. The full range of products of Lisun are in strict accordance with the quality management and control of ISO9001:2008 requirements for R & D and production; Lisun is also the member unit of global lighting CIE association, all products are according to CIE requirements; in addition, all products of Lisun are certified by CE and get the qualification of the EU.

Tuesday, February 25, 2020

Introduction of Conducted Immunity Testing

This page is a brief introduction and description for conducted immunity testing which based on IEC 61000-4-4 fast transient burst test, IEC 61000-4-5 lightning surge test, IEC 61000-4-11 voltage cycle drop test and IEC 61000-4-12 ring wave test.

IEC 61000-4-4 establishes a common and reproducible reference for evaluating the immunity of electrical and electronic equipment when subjected to electrical fast transient/bursts on supply, signal, control and earth ports. The test method documented in this part of IEC 61000 describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon.

IEC 61000-4-5 relates to the immunity requirements, test methods, and range of recommended test levels for equipment to unidirectional surges caused by over-voltages from switching and lightning transients. Several test levels are defined which relate to different environment and installation conditions. These requirements are developed for and are applicable to electrical and electronic equipment. The object of this standard is to establish a common reference for evaluating the immunity of electrical and electronic equipment when subjected to surges.

IEC 61000-4-11 defines the immunity test methods and range of preferred test levels for electrical and electronic equipment connected to low-voltage power supply networks for voltage dips, short interruptions, and voltage variations. This standard applies to electrical and electronic equipment having a rated input current not exceeding 16 A per phase, for connection to 50 Hz or 60 Hz A.C. networks. It does not apply to electrical and electronic equipment for connection to 400 Hz A.C. networks.

IEC 61000-4-12 relates to the immunity requirements and test methods for electrical and electronic equipment, under operational conditions, to non-repetitive damped oscillatory transients (ring waves) occurring in low-voltage power, control and signal lines supplied by public and non-public networks. The object of this basic standard is to establish the immunity requirements and a common reference for evaluating in a laboratory the performance of electrical and electronic equipment intended for residential, commercial and industrial applications, as well as of equipment intended for power stations and substations, as applicable.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

IEC 61000-4-4 establishes a common and reproducible reference for evaluating the immunity of electrical and electronic equipment when subjected to electrical fast transient/bursts on supply, signal, control and earth ports. The test method documented in this part of IEC 61000 describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon.

IEC 61000-4-5 relates to the immunity requirements, test methods, and range of recommended test levels for equipment to unidirectional surges caused by over-voltages from switching and lightning transients. Several test levels are defined which relate to different environment and installation conditions. These requirements are developed for and are applicable to electrical and electronic equipment. The object of this standard is to establish a common reference for evaluating the immunity of electrical and electronic equipment when subjected to surges.

IEC 61000-4-11 defines the immunity test methods and range of preferred test levels for electrical and electronic equipment connected to low-voltage power supply networks for voltage dips, short interruptions, and voltage variations. This standard applies to electrical and electronic equipment having a rated input current not exceeding 16 A per phase, for connection to 50 Hz or 60 Hz A.C. networks. It does not apply to electrical and electronic equipment for connection to 400 Hz A.C. networks.

IEC 61000-4-12 relates to the immunity requirements and test methods for electrical and electronic equipment, under operational conditions, to non-repetitive damped oscillatory transients (ring waves) occurring in low-voltage power, control and signal lines supplied by public and non-public networks. The object of this basic standard is to establish the immunity requirements and a common reference for evaluating in a laboratory the performance of electrical and electronic equipment intended for residential, commercial and industrial applications, as well as of equipment intended for power stations and substations, as applicable.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Interpretation of the latest American Energy Star IES LM-79-19 standard

Spanish version LM-79-19 download: ANSI/IES LM-79-19 Mediciones Fotométricas y Eléctricas de Productos de Iluminación de Estado Sólido (SSL)

ANSI (American National Standards Institute) and IES(Illuminating Engineering Society of North America) officially released the latest version of the IES LM-79-19 standard in May 2019, it will replace the LM-79-08 version. LISUN interpreted the new standard as follows:

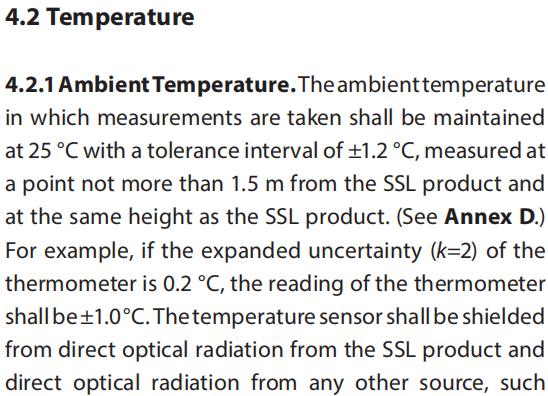

1. Test Environment (4.2.1 / 4.3 / 4.7 on Page 2 / Page 3 / Page 4 of the standard)

1.1 Ambient Temperature:25℃±1.2℃

1.2 Humidity: 10%-65%

1.3 Airflow: 0.2m/s

2. Test Circuit Requirements (5.2.1 on Page 4 of the standard): Power supply request4-terminal connection, 2- terminal power supply, 2- terminal feedback

3. AC Power Supply (5.1.2 on page 4 of the standard)

3.1 Load regulation rate: ±0.2%

3.2 Accuracy requirements: 0.1% (reading) + 0.1% (range)

3.3 Example: If the power supply of lamp is 220V and the range is 300V, the actual output voltage should be 220V ± 0.26V

LISUN LSP-500VAR Pure Sine Wave AC Power Source fully meet the requirement, click here to learn more about it.

4. DC Power Supply (5.1.3 on Page 4 of the standard)

4.1 Load regulation rate: ±0.2%

4.2 Accuracy requirements: Current and voltage are both 0.1%

LISUN DC3010 Digital CC and CV DC Power Supply fully meet the requirement, click here to learn more about it.

5. AC Power Meters (5.3.2 on Page 5 of the Standard, 5.3.4 on Page 5 of the Standard)

5.1 Sampling frequency : 1kHz-100kHz

5.2 The meter shall have an expanded uncertainty (k=2) of 0.6% or less for measurement frequencies ranging from 0.5Hz to 1kHz, and an expanded unvertainty (k=2) of 2.0% or less for measurement frequencies ranging from 1kHz to 100kHz

5.3 Total Harmonic Distortion Measurement 2~50 times

LISUN LS2050 Digital Power Meter fully meet the requirement. Click here to learn more about it.

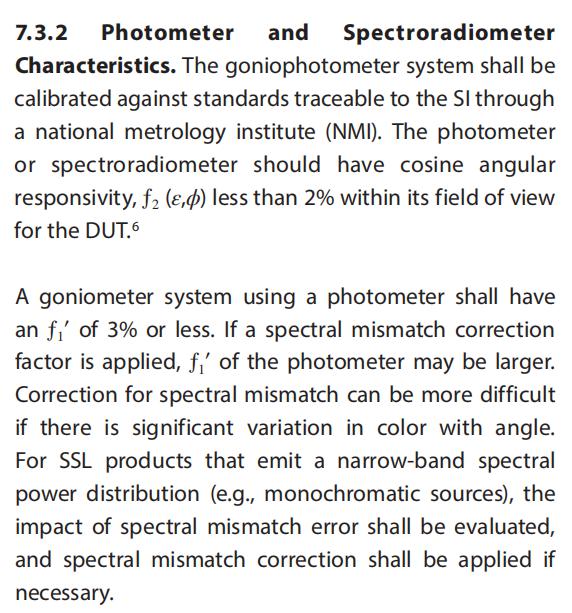

6. Photometric probe (7.3.2 on Page 9 of the Standard)

6.1 Cosine angular responsivity f2(ε,φ) less than 2%

6.2 f1’ less than 3%

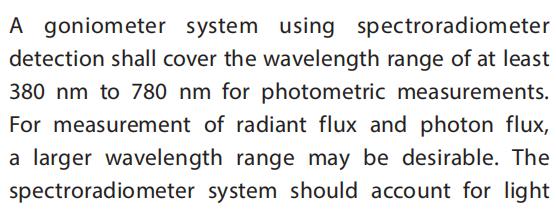

7. Spectroradiometer (7.3.2 on Page 9 of standard)

7.1 380-780nm

7.2 Bandwidth not greater than 5nm

7.3 Wevelength unvertainty within 0.5nm

7.4 Sensitivity: Refer to LM-78-17 (7.2 on Page 7 of standard)

LISUN LPCE-2 High Precision Spectroradiometer Integrating Sphere System fully meet the requierment, click here to learn more about it.

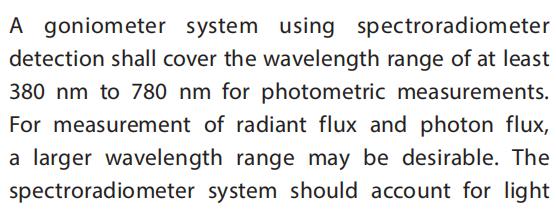

LPCE-2(LMS 9000) Spectrophotometer & Integrating Sphere Test System

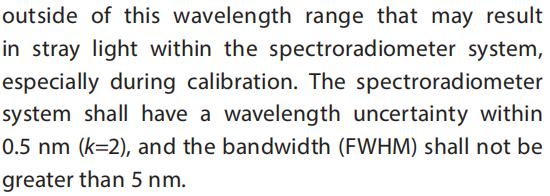

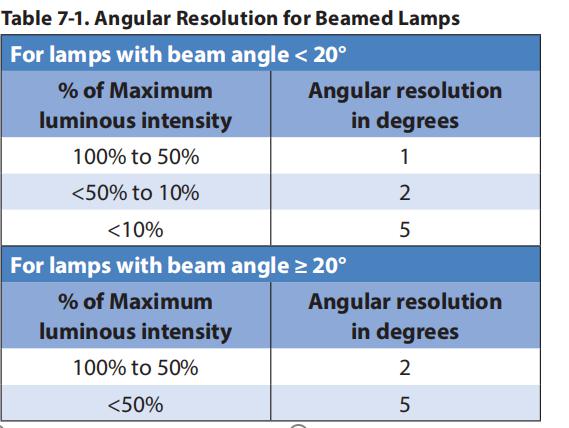

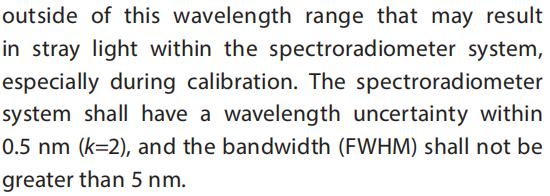

8. Goniometer variable angle tester (7.3.3 on Page 9 of standard)

8.1 For lamps with beam angle < 20°: 100%-50% maximum luminous intensity choose no more than 1 degree angular resolution; 50%-10% maximum luminous intensity choose no more than 2 degrees angular resolution; 10%-0% maximum luminous intensity choose no more than 5 degrees angular resolution;

8.2 For lamps with beam angle ≥20°: 100%-50% maximum luminous intensity choose no more than 2 degrees angular resolution; 50%-0% maximum luminous intensity choose no more than 5 degrees angular resolution。

LISUN LSG-5000CCD Moving Detector Goniospectroradiometer fully meet the requierment, click here to learn more about it.

LSG-5000CCD Moving Detector Goniospectroradiometer

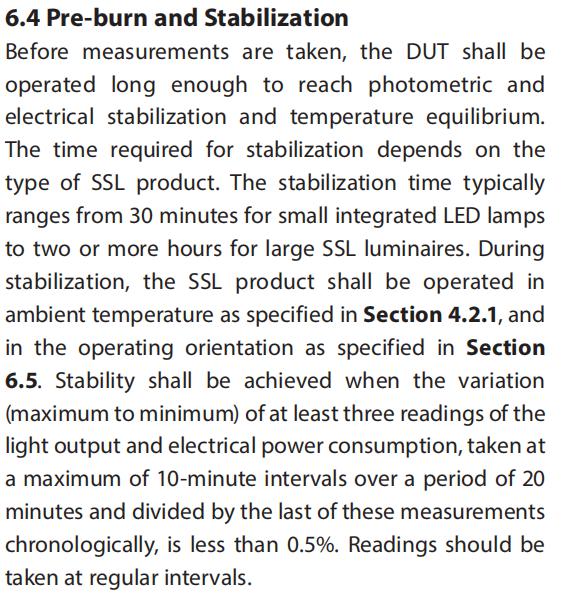

9. Stabilization Requirement (6.4 on Page 7 of standard)

9.1 Monitor for at least 30 minutes

9.2 Take at least three readings of the light output and electrical power consumption taken over period of 20 minutes

9.3 Stability shall be achieved when the variation (maximum to minimum) divided by the last measurements is less than 0.5%

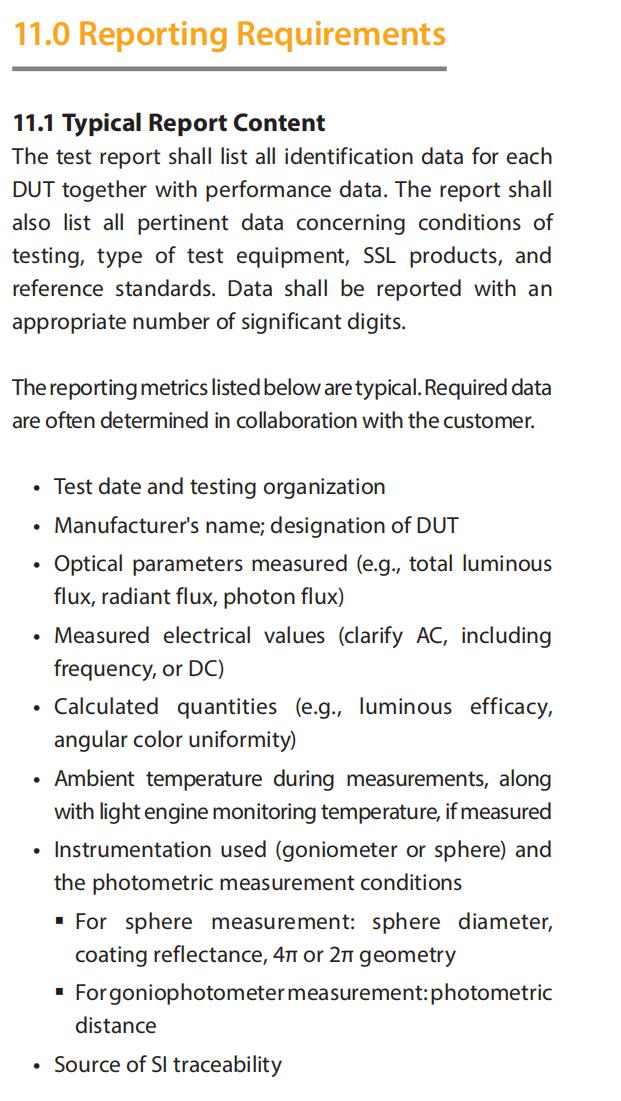

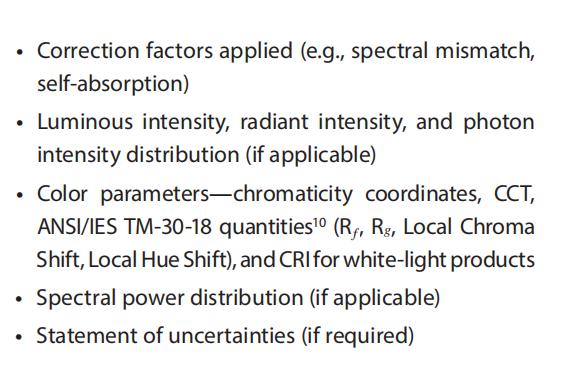

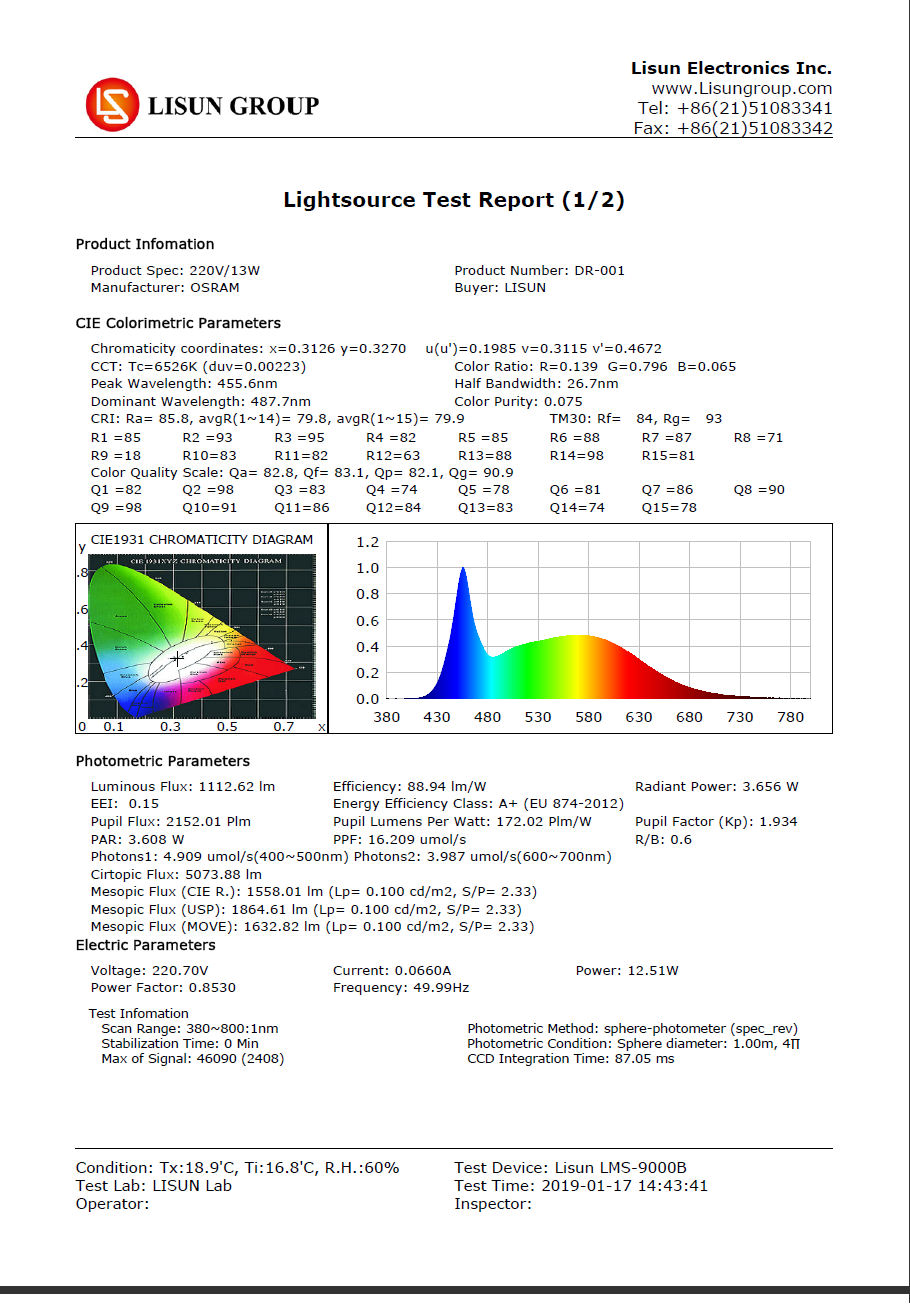

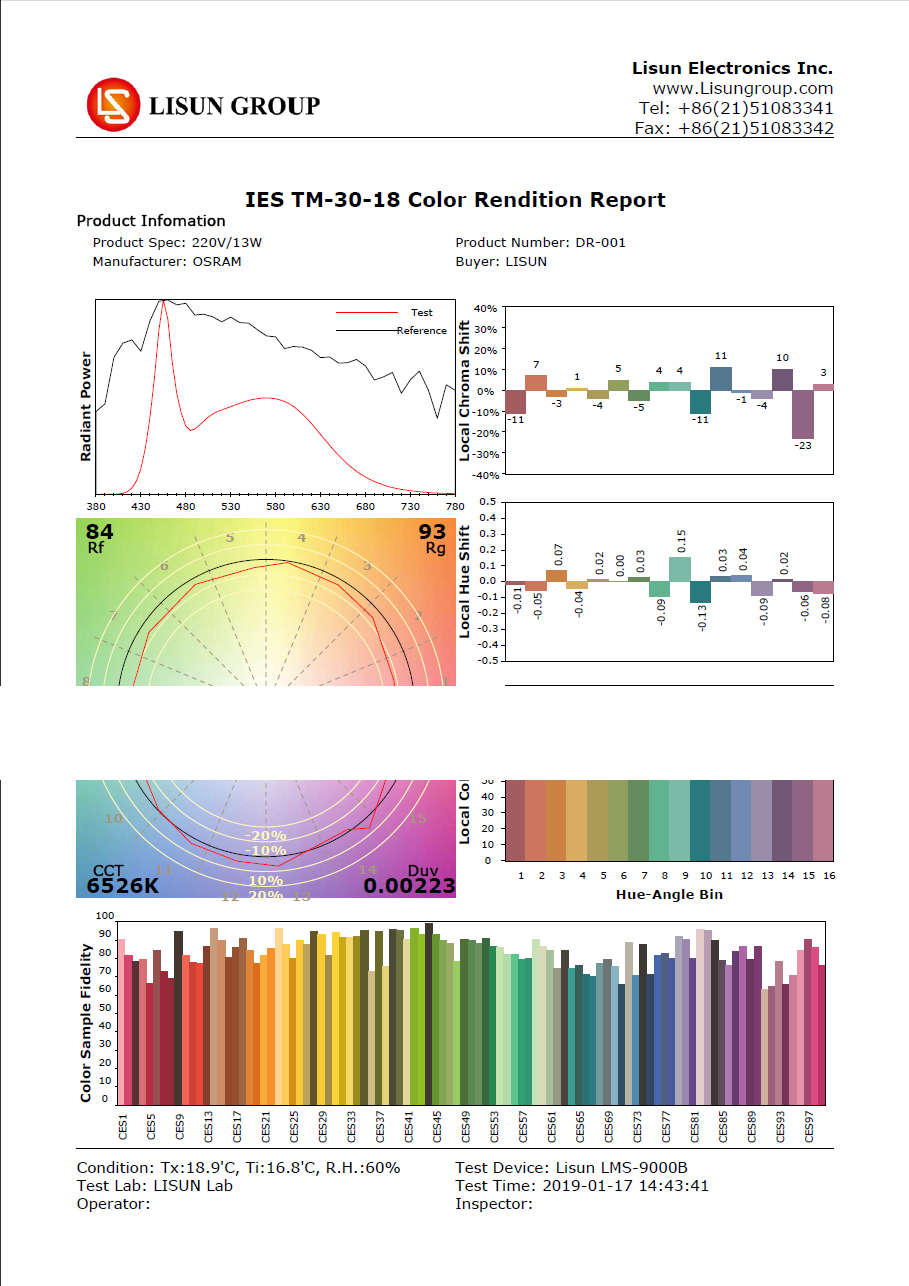

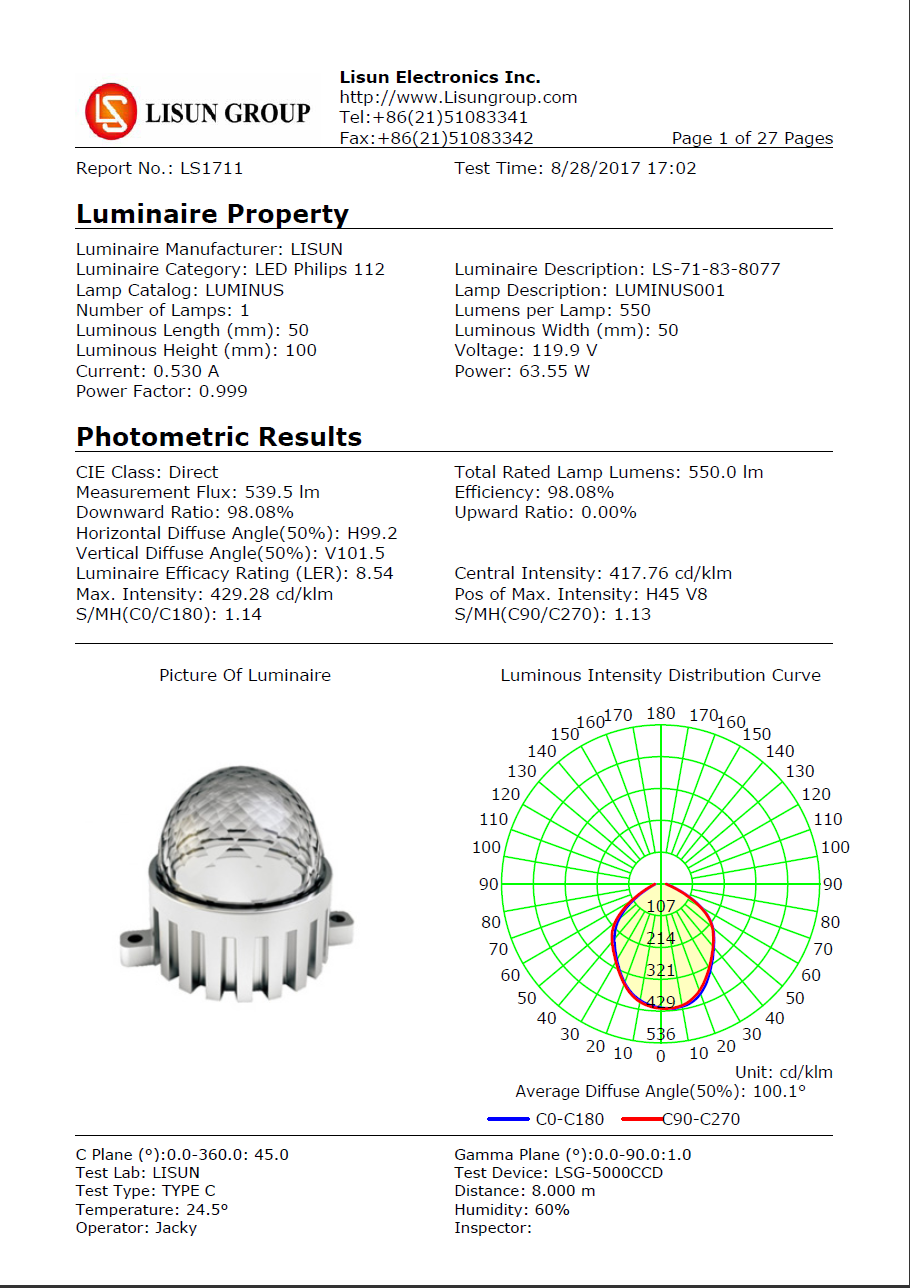

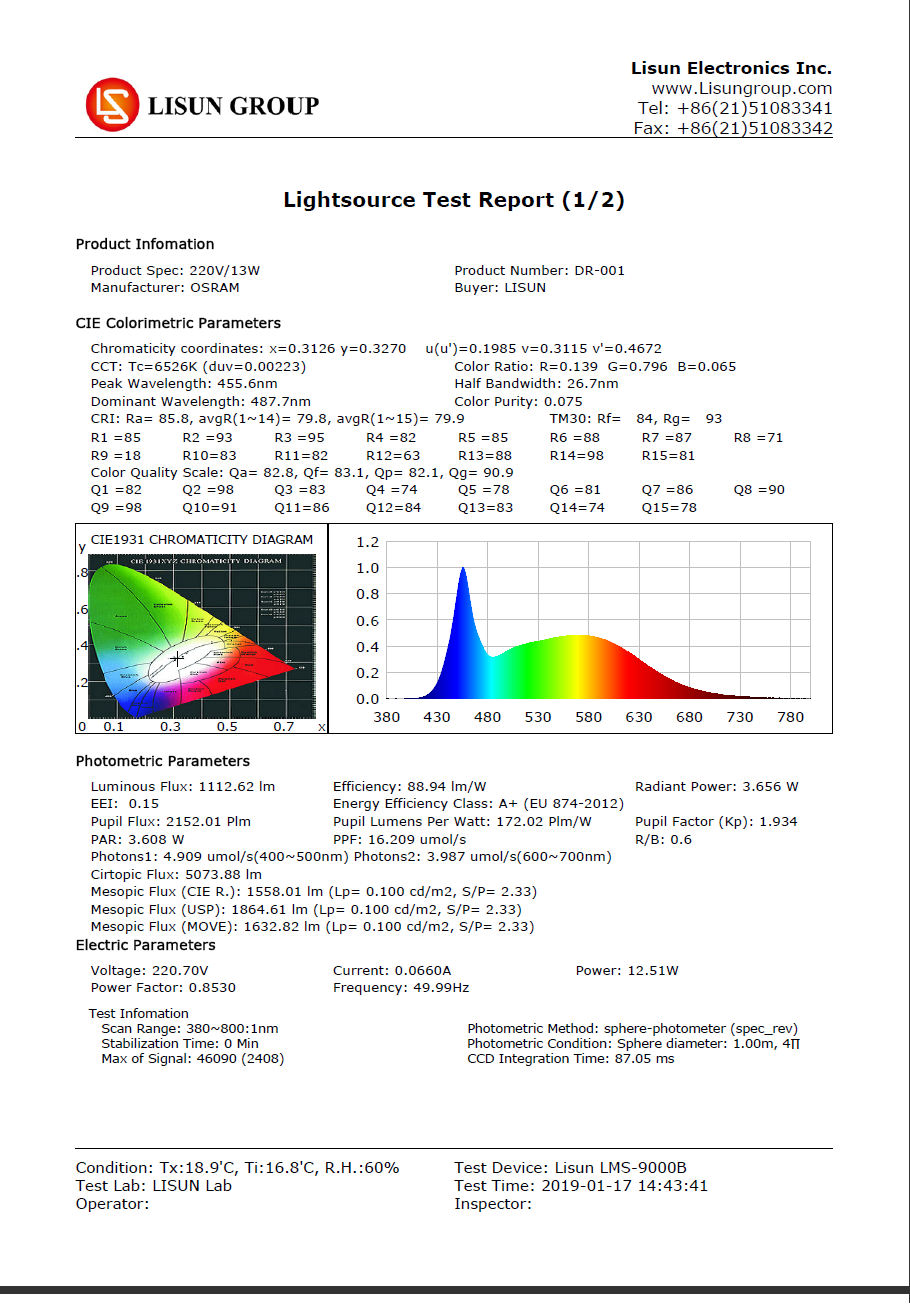

10. Test Report(11.1 on Page 12 of the standard)

10.1 Test date and testing organization

10.2 Manufacture’s name

10.3 Optical parameters measured (e.g., total luminous flux, radiant flux, photon flux)

10.4 Measured electrical values (Clarify AC, including frequency, or DC)

10.5 Calculated quantities (e.g., luminous efficacy, angular color uniformity)

10.6 Ambient temperature

10.7 Measurement conditions. For sphere measurement: Sphere diameter, coating reflectance, 4π or 2π geometry. For goniophotometer measurement: Photometric distance

10.8 SI (source of traceability)

10.9 Self-absorption correction factor

10.10 Luminous intensity

10.11 Chromaticity coordinates, CCT, CRI

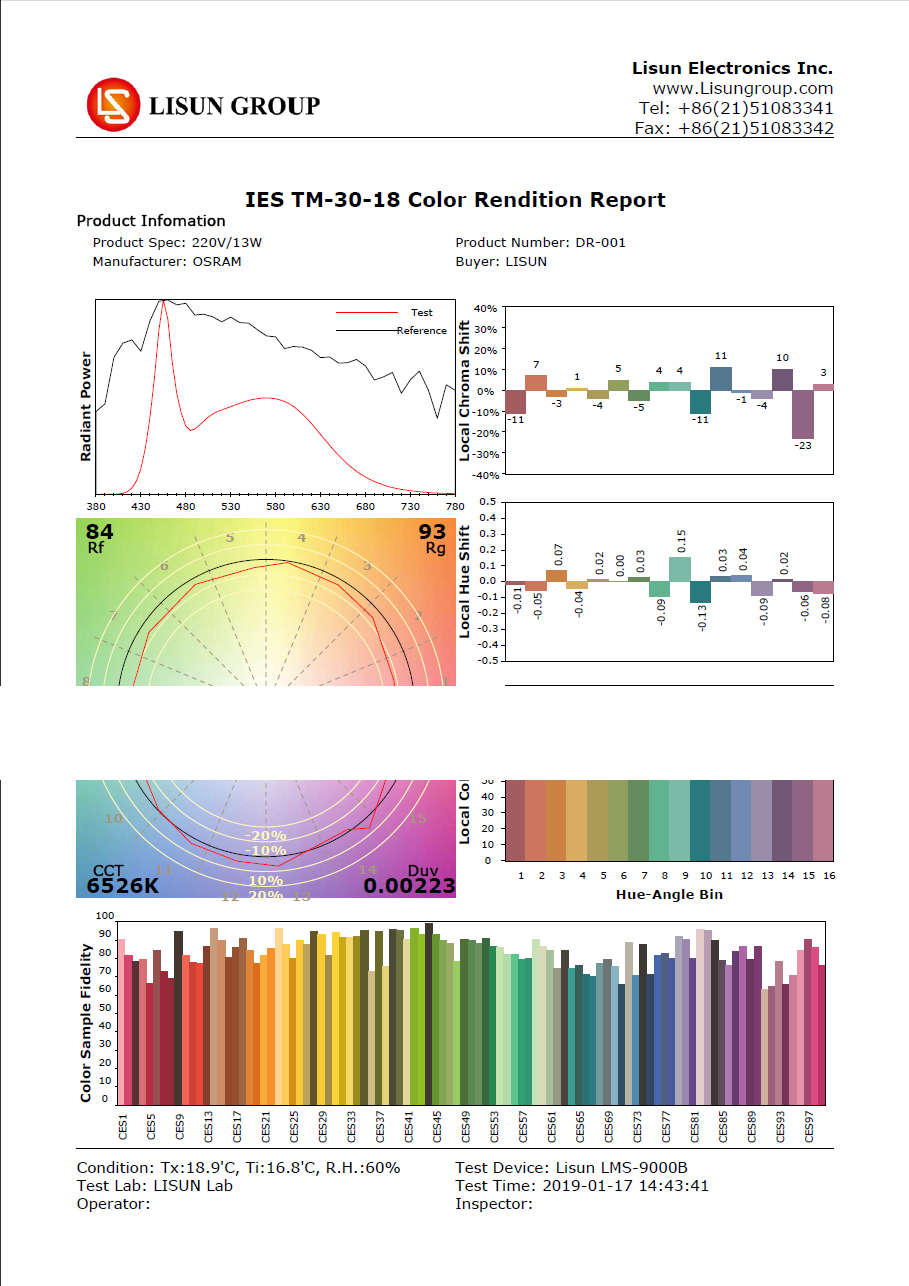

10.12 ANSI/IES TM-30-18 (Rg Rf,Local Chroma Shift, Local Hue Shift)

10.13 Spectral power distribution

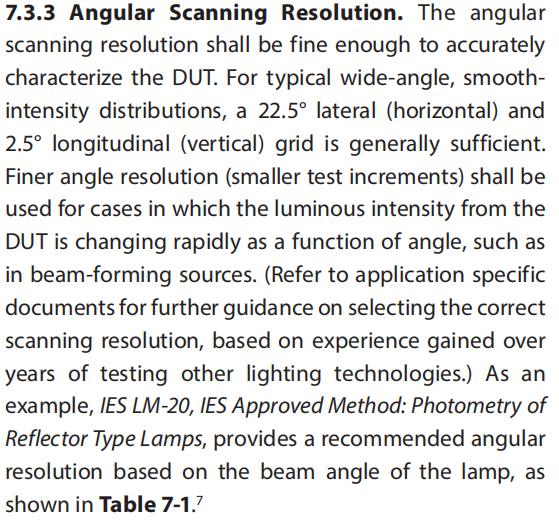

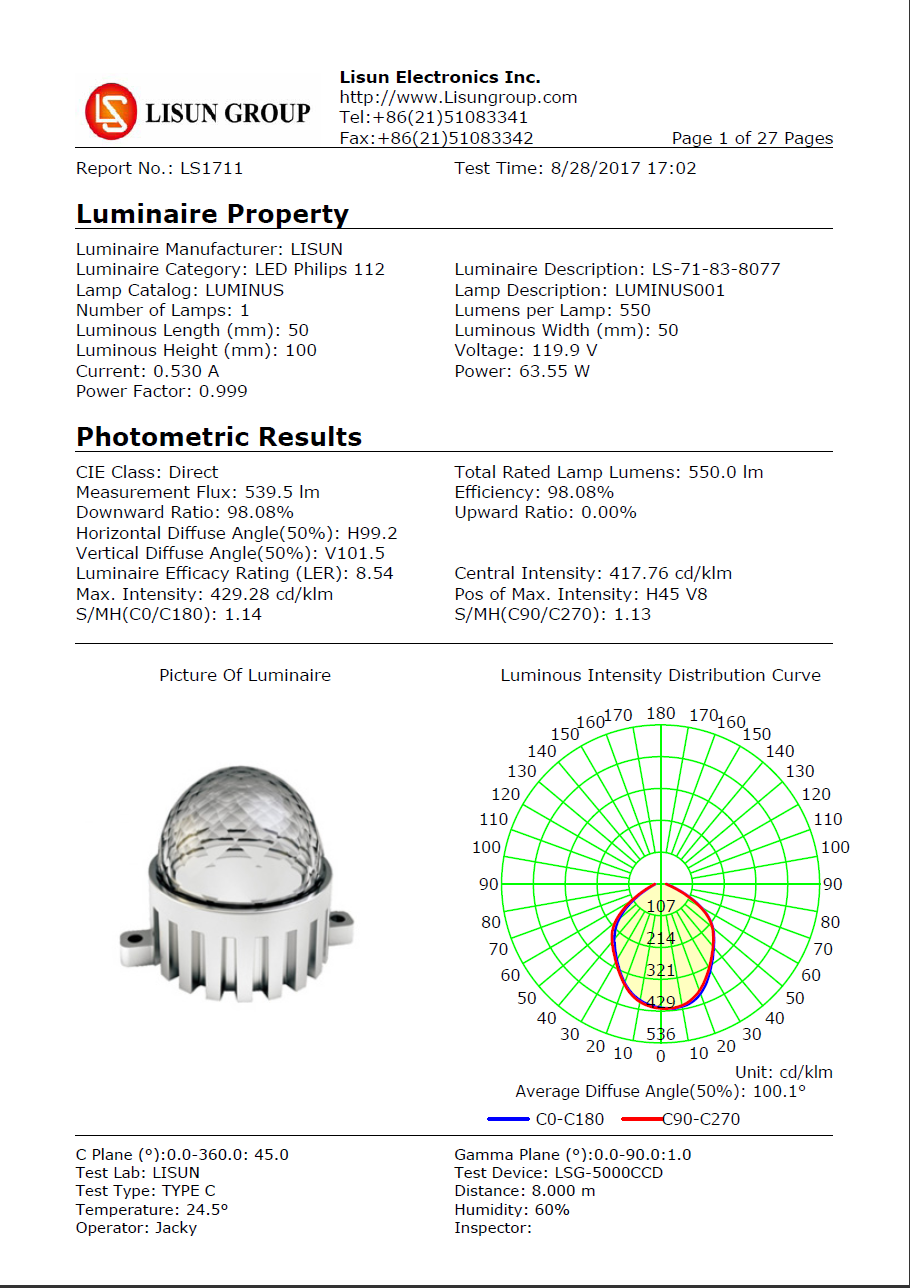

Below is the test report of LPCE-2 High Precision Spectroradiometer Integrating Sphere System and LSG-5000CCD Moving Detector Goniospectroradiometer test system:

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, IP Waterproof Test Equipment, Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

ANSI (American National Standards Institute) and IES(Illuminating Engineering Society of North America) officially released the latest version of the IES LM-79-19 standard in May 2019, it will replace the LM-79-08 version. LISUN interpreted the new standard as follows:

1. Test Environment (4.2.1 / 4.3 / 4.7 on Page 2 / Page 3 / Page 4 of the standard)

1.1 Ambient Temperature:25℃±1.2℃

1.2 Humidity: 10%-65%

1.3 Airflow: 0.2m/s

2. Test Circuit Requirements (5.2.1 on Page 4 of the standard): Power supply request4-terminal connection, 2- terminal power supply, 2- terminal feedback

3. AC Power Supply (5.1.2 on page 4 of the standard)

3.1 Load regulation rate: ±0.2%

3.2 Accuracy requirements: 0.1% (reading) + 0.1% (range)

3.3 Example: If the power supply of lamp is 220V and the range is 300V, the actual output voltage should be 220V ± 0.26V

LISUN LSP-500VAR Pure Sine Wave AC Power Source fully meet the requirement, click here to learn more about it.

4. DC Power Supply (5.1.3 on Page 4 of the standard)

4.1 Load regulation rate: ±0.2%

4.2 Accuracy requirements: Current and voltage are both 0.1%

LISUN DC3010 Digital CC and CV DC Power Supply fully meet the requirement, click here to learn more about it.

5. AC Power Meters (5.3.2 on Page 5 of the Standard, 5.3.4 on Page 5 of the Standard)

5.1 Sampling frequency : 1kHz-100kHz

5.2 The meter shall have an expanded uncertainty (k=2) of 0.6% or less for measurement frequencies ranging from 0.5Hz to 1kHz, and an expanded unvertainty (k=2) of 2.0% or less for measurement frequencies ranging from 1kHz to 100kHz

5.3 Total Harmonic Distortion Measurement 2~50 times

LISUN LS2050 Digital Power Meter fully meet the requirement. Click here to learn more about it.

6. Photometric probe (7.3.2 on Page 9 of the Standard)

6.1 Cosine angular responsivity f2(ε,φ) less than 2%

6.2 f1’ less than 3%

7. Spectroradiometer (7.3.2 on Page 9 of standard)

7.1 380-780nm

7.2 Bandwidth not greater than 5nm

7.3 Wevelength unvertainty within 0.5nm

7.4 Sensitivity: Refer to LM-78-17 (7.2 on Page 7 of standard)

LISUN LPCE-2 High Precision Spectroradiometer Integrating Sphere System fully meet the requierment, click here to learn more about it.

LPCE-2(LMS 9000) Spectrophotometer & Integrating Sphere Test System

8. Goniometer variable angle tester (7.3.3 on Page 9 of standard)

8.1 For lamps with beam angle < 20°: 100%-50% maximum luminous intensity choose no more than 1 degree angular resolution; 50%-10% maximum luminous intensity choose no more than 2 degrees angular resolution; 10%-0% maximum luminous intensity choose no more than 5 degrees angular resolution;

8.2 For lamps with beam angle ≥20°: 100%-50% maximum luminous intensity choose no more than 2 degrees angular resolution; 50%-0% maximum luminous intensity choose no more than 5 degrees angular resolution。

LISUN LSG-5000CCD Moving Detector Goniospectroradiometer fully meet the requierment, click here to learn more about it.

LSG-5000CCD Moving Detector Goniospectroradiometer

9. Stabilization Requirement (6.4 on Page 7 of standard)

9.1 Monitor for at least 30 minutes

9.2 Take at least three readings of the light output and electrical power consumption taken over period of 20 minutes

9.3 Stability shall be achieved when the variation (maximum to minimum) divided by the last measurements is less than 0.5%

10. Test Report(11.1 on Page 12 of the standard)

10.1 Test date and testing organization

10.2 Manufacture’s name

10.3 Optical parameters measured (e.g., total luminous flux, radiant flux, photon flux)

10.4 Measured electrical values (Clarify AC, including frequency, or DC)

10.5 Calculated quantities (e.g., luminous efficacy, angular color uniformity)

10.6 Ambient temperature

10.7 Measurement conditions. For sphere measurement: Sphere diameter, coating reflectance, 4π or 2π geometry. For goniophotometer measurement: Photometric distance

10.8 SI (source of traceability)

10.9 Self-absorption correction factor

10.10 Luminous intensity

10.11 Chromaticity coordinates, CCT, CRI

10.12 ANSI/IES TM-30-18 (Rg Rf,Local Chroma Shift, Local Hue Shift)

10.13 Spectral power distribution

Below is the test report of LPCE-2 High Precision Spectroradiometer Integrating Sphere System and LSG-5000CCD Moving Detector Goniospectroradiometer test system:

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, IP Waterproof Test Equipment, Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

Monday, February 24, 2020

How do you choose integrating sphere if you test small size but high power HID lamp?

HID lamp is high intensity discharge lamp. High pressure sodium lamp, high pressure mercury lamp, xenon lamp, metal halide lamp are all belong to HID lamp.

We generally use Integrating Sphere Spectroradiometer Test System to test the photometric, colorimetric and electrometric parameters. Generally we suggest the diameter size of Integrating Sphere according to the size of lamp under test. If you test single LED or LED chips, we recommend small integrating sphere such as IS-0.3M or IS-0.5M. 1.2m luminaries should at least use D=1.5M integrating sphere to measure.

If you test high power small size HID lamp, how do we choose Integrating Sphere? If the power of HID lamp is over 200W, we generally recommend use D=2.0m integrating sphere, we will not suggest small integrating sphere because of these reasons:

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

We generally use Integrating Sphere Spectroradiometer Test System to test the photometric, colorimetric and electrometric parameters. Generally we suggest the diameter size of Integrating Sphere according to the size of lamp under test. If you test single LED or LED chips, we recommend small integrating sphere such as IS-0.3M or IS-0.5M. 1.2m luminaries should at least use D=1.5M integrating sphere to measure.

If you test high power small size HID lamp, how do we choose Integrating Sphere? If the power of HID lamp is over 200W, we generally recommend use D=2.0m integrating sphere, we will not suggest small integrating sphere because of these reasons:

- If integrating sphere is too small, cooling is not good, the temperature of integrating sphere will affect the test result.

- The signal will be too strong, the integration time will be very shot and the test error for lumen will increase.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

IEC 61000-4-5: Surge Test and Measurement Techniques

Surge generator anti-interference measurement is based on the international standard IEC 61000-4-5.

SG61000-5_Surge Generator

SG61000-5_Surge Generator

1 Test objective

The entire lightning stroke in the nature (namely the indirect thunder such as the lighting stroke between the clouds, or the lighting stroke happened to the adjacent objects) can induce the surge voltage and current in outdoor aerial. Besides, huge surge voltage and current will also be induced in the supply circuit of the instant switch in the power station or switching station. The common characteristics of the two kinds of surge include high energy (compared with the energy, the static electricity is P joule level, pulse group is the millijoule level, lightning surge is hundreds of the joule level, which is one million times of the former two interfering energy), slow waveform (microsecond level, but the static electricity and pulse group are nanosecond level, even the sub nanosecond level), and low recurrence frequency.

IEC 61000-4-5 is a standard that provides an objective evaluation on the resistance to surge interference ability for the electrical and electronic equipment through the experiment of simulating lighting surge.

2 Surge generators

This standard has mentioned two kinds of surge generators, which respectively simulate the situation of the power line and the communication line. The waveforms of the two kinds of surge are different because of the different line impedance.

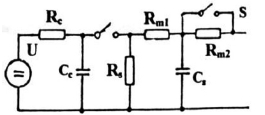

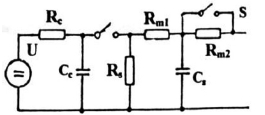

(1)Comprehensive wave generator used for the power lines test

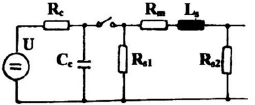

“Comprehensive wave” refers to the waveform parameters formed by the voltage wave and the current wave regulated by the standard in a generator (when the output terminal of the generator is open circuit, it will form the voltage surge wave; when the output terminal of the generator is short circuit, and it will form the current surge wave). The requirement of the generator line and the waveform is shown as the following figures:

IEC 61000-4-5: Surge Test and Measurement Techniques

U: High-voltage power supply

Rs: Pulse duration forming resistor

Rc: Charging resistor

Rm: Impedance matching resistor

Cc: Reservoir capacitance

L: Rising time forming resistor

IEC 61000-4-5: Surge Test and Measurement Techniques

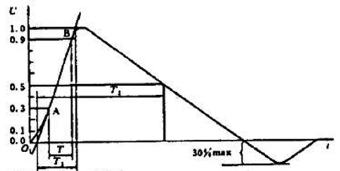

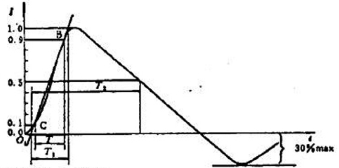

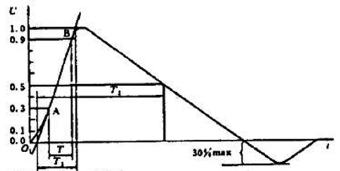

Front wave time: T1=1.67XT=1.2μs±30%

Half peak value time: T2=50μs±20%

1.2/50μs Open-circuit voltage waveform (based on IEC 60-1 waveform regulation)

IEC 61000-4-5: Surge Test and Measurement Techniques

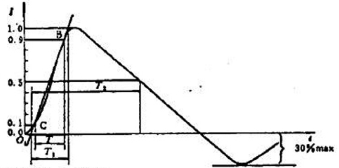

Front wave time: T1=1.25XT=8μs±30%

Half peak value time: T2=20μs±20%

8/20μs Open-circuit voltage waveform (based on IEC 60-1 waveform regulation)

The basic requirement of the comprehensive generator:

Open-circuit output voltage (±10%): 0.5kVP to 4kVP

Short-circuit output current (±10%): 0.25kAP to 2kAP

Generator resistance: 2Ω (it is the key to connect the open-circuit voltage wave and the short-circuit current wave)

Additional resistance: 10Ω or 40Ω, form 12Ω or 42Ω internal resistance

Surge output polarity: positive / negative

Surge phase shifting range:0°~360° (surge output synchronizes with the power supply)

Maximum repetition frequency: at least once per minute

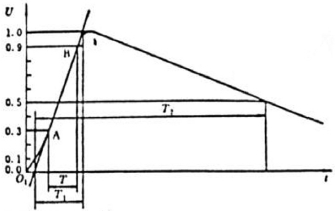

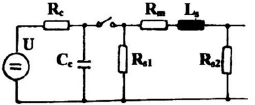

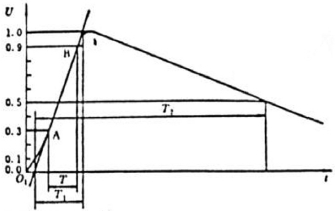

(2)10/700μs surge wave generator used for telecommunication line

The generator line and the waveform are shown as the following figure:

U: High-voltage power supply

Rs: Pulse duration forming resistor

Rc: Charging resistor

Cc: Reservoir capacitance (20μF)

Rm: Impedance matching resistor (Rm1=15Ω, Rm2=25Ω)

Cs: Rising time forming resistor (0.2μF)

SG61000-5_Surge Generator

SG61000-5_Surge Generator

1 Test objective

The entire lightning stroke in the nature (namely the indirect thunder such as the lighting stroke between the clouds, or the lighting stroke happened to the adjacent objects) can induce the surge voltage and current in outdoor aerial. Besides, huge surge voltage and current will also be induced in the supply circuit of the instant switch in the power station or switching station. The common characteristics of the two kinds of surge include high energy (compared with the energy, the static electricity is P joule level, pulse group is the millijoule level, lightning surge is hundreds of the joule level, which is one million times of the former two interfering energy), slow waveform (microsecond level, but the static electricity and pulse group are nanosecond level, even the sub nanosecond level), and low recurrence frequency.

IEC 61000-4-5 is a standard that provides an objective evaluation on the resistance to surge interference ability for the electrical and electronic equipment through the experiment of simulating lighting surge.

2 Surge generators

This standard has mentioned two kinds of surge generators, which respectively simulate the situation of the power line and the communication line. The waveforms of the two kinds of surge are different because of the different line impedance.

(1)Comprehensive wave generator used for the power lines test

“Comprehensive wave” refers to the waveform parameters formed by the voltage wave and the current wave regulated by the standard in a generator (when the output terminal of the generator is open circuit, it will form the voltage surge wave; when the output terminal of the generator is short circuit, and it will form the current surge wave). The requirement of the generator line and the waveform is shown as the following figures:

IEC 61000-4-5: Surge Test and Measurement Techniques

U: High-voltage power supply

Rs: Pulse duration forming resistor

Rc: Charging resistor

Rm: Impedance matching resistor

Cc: Reservoir capacitance

L: Rising time forming resistor

IEC 61000-4-5: Surge Test and Measurement Techniques

Front wave time: T1=1.67XT=1.2μs±30%

Half peak value time: T2=50μs±20%

1.2/50μs Open-circuit voltage waveform (based on IEC 60-1 waveform regulation)

IEC 61000-4-5: Surge Test and Measurement Techniques

Front wave time: T1=1.25XT=8μs±30%

Half peak value time: T2=20μs±20%

8/20μs Open-circuit voltage waveform (based on IEC 60-1 waveform regulation)

The basic requirement of the comprehensive generator:

Open-circuit output voltage (±10%): 0.5kVP to 4kVP

Short-circuit output current (±10%): 0.25kAP to 2kAP

Generator resistance: 2Ω (it is the key to connect the open-circuit voltage wave and the short-circuit current wave)

Additional resistance: 10Ω or 40Ω, form 12Ω or 42Ω internal resistance

Surge output polarity: positive / negative

Surge phase shifting range:0°~360° (surge output synchronizes with the power supply)

Maximum repetition frequency: at least once per minute

(2)10/700μs surge wave generator used for telecommunication line

The generator line and the waveform are shown as the following figure:

IEC 61000-4-5: Surge Test and Measurement Techniques

U: High-voltage power supply

Rs: Pulse duration forming resistor

Rc: Charging resistor

Cc: Reservoir capacitance (20μF)

Rm: Impedance matching resistor (Rm1=15Ω, Rm2=25Ω)

Cs: Rising time forming resistor (0.2μF)

IEC 61000-4-5: Surge Test and Measurement Techniques

S: Switch, this switch should be closed when using the external matching resistance

Front wave time: T1=1.67XT=10μs±30%

Half peak value time: T2=700μs±20%

10/700μs Open-circuit voltage waveform (based on CCITT waveform regulation)Basic requirement of the generator:Open-circuit voltage wave:10/700μsOpen-circuit output voltage(±10%): 0.5kVP to 4kVP

Generator resistance: 40Ω

Surge output polarity: Positive / negative

Half peak value time: T2=700μs±20%

10/700μs Open-circuit voltage waveform (based on CCITT waveform regulation)Basic requirement of the generator:Open-circuit voltage wave:10/700μsOpen-circuit output voltage(±10%): 0.5kVP to 4kVP

Generator resistance: 40Ω

Surge output polarity: Positive / negative

3 Test methods

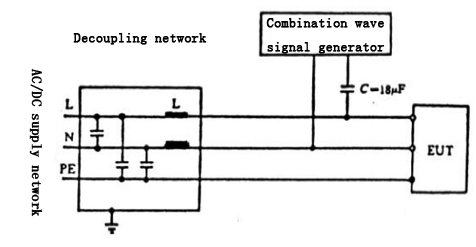

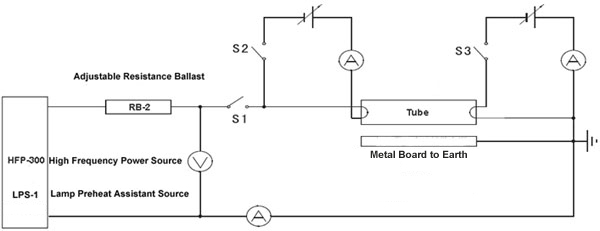

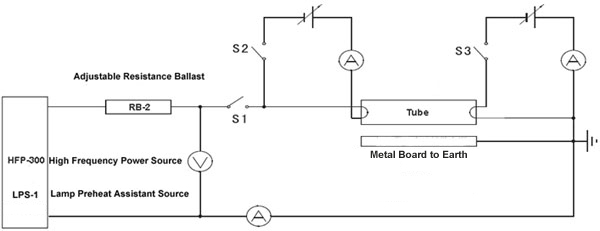

Since the voltage and the current of the surge test are relatively slow, the configuration of the lab is rather simple. The power circuit test is finished through coupling decoupling network. The following figure is the single-phase test circuit diagram which has the requirement of the differential mode and common mode test.

Since the voltage and the current of the surge test are relatively slow, the configuration of the lab is rather simple. The power circuit test is finished through coupling decoupling network. The following figure is the single-phase test circuit diagram which has the requirement of the differential mode and common mode test.

IEC 61000-4-5: Surge Test and Measurement Techniques

4 Attention in the test

(1)Protective measures must be taken in accordance with the requirement of the manufacturer before the test.

(2) The test rate is once per minute. It should not be too quick so as to form a recovery process for protecting the machine’s performance. As a matter of fact, it is impossible for the natural lighting phenomenon and the large switch of the transformer substation to have very high repetition rate. In general, there are five -times test for each positive and negative polarity.

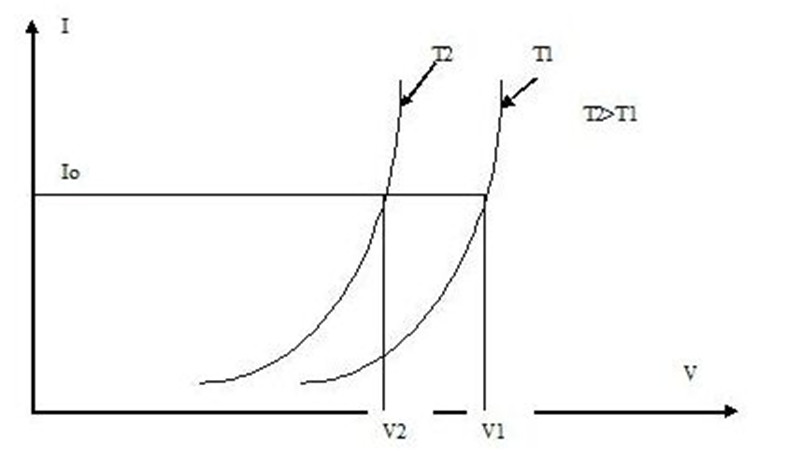

(3) The voltage should be gradually tested from low level to high level to avoid the false scent of the sample I-V nonlinear characteristics. In addition, the test voltage should be confirmed not to exceed the requirement of the product standard in order to avoid the unnecessary damage.

5 Severe degree of the test

The severe degree of the test can be divided into 1, 2, 3, and 4 and X level. Level 13 parameter of the power circuit differential mode is not given, the other levels are respectively 0.5kV、1kV、2kV and undetermined. Each level parameter of the power circuit common mode test is 0.5kV、1kV、2kV、4kV and undetermined.

The severe degree of the test depends on the environment (the environment that may suffer the surge) and the installation condition; it is mainly divided into the following types:

Level 1: Better protective environment, such as the control room of the factories or the power station.

Level 2: Certain protective environment such as factories with no strong interference.

Level 3: Common electromagnetic harassment environment without specified installation requirement for the equipment such as the cable network of common installation, industrial work place and power substation.

Level 4: Severe harassment environment such as civil aerial, high-pressure power substation without protection.

Level X: Special level should be confirmed after the consultation of the user and the manufacturer.Selection of the product level depends on the product standard.

6 Comment on the standards

At present, there are many standards mentioning the situation of using 1.2/50μs lighting to do the test, but the different standard has different test objective. For example, high-pressure test also mentioned the lighting test for the impulse withstand voltage test with the high-pressure and high-resistance generator. At this moment, although the voltage of the generator is high, the energy is not huge. This kind of test is conducted in the off-line state of the equipment. On the contrary, IEC 61000-4-5 standard requires conducting the surge anti-interference measurement. Due to the low circuit impedance, the output impedance of the generator is also required to be low. In this way, the generator suitable for surge anti-interference measurement not only needs to have high output voltage, but also needs to have low output impedance and large energy output characteristics. Since the equipment conducts the measurement in the on-line state, coupling and decoupling network should be used. It can be seen that the above mentioned two kinds of experiments are totally different, which should not be confused.

Lisun Instruments Limited was found by LISUN GROUP in 2003.LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer Integrating Sphere System, LED Test Instruments, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test ,Dustproof Test , High and Low temperature Humidity Chamber, Plug and Switch Testing,etc.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

(1)Protective measures must be taken in accordance with the requirement of the manufacturer before the test.

(2) The test rate is once per minute. It should not be too quick so as to form a recovery process for protecting the machine’s performance. As a matter of fact, it is impossible for the natural lighting phenomenon and the large switch of the transformer substation to have very high repetition rate. In general, there are five -times test for each positive and negative polarity.

(3) The voltage should be gradually tested from low level to high level to avoid the false scent of the sample I-V nonlinear characteristics. In addition, the test voltage should be confirmed not to exceed the requirement of the product standard in order to avoid the unnecessary damage.

5 Severe degree of the test

The severe degree of the test can be divided into 1, 2, 3, and 4 and X level. Level 13 parameter of the power circuit differential mode is not given, the other levels are respectively 0.5kV、1kV、2kV and undetermined. Each level parameter of the power circuit common mode test is 0.5kV、1kV、2kV、4kV and undetermined.

The severe degree of the test depends on the environment (the environment that may suffer the surge) and the installation condition; it is mainly divided into the following types:

Level 1: Better protective environment, such as the control room of the factories or the power station.

Level 2: Certain protective environment such as factories with no strong interference.

Level 3: Common electromagnetic harassment environment without specified installation requirement for the equipment such as the cable network of common installation, industrial work place and power substation.

Level 4: Severe harassment environment such as civil aerial, high-pressure power substation without protection.

Level X: Special level should be confirmed after the consultation of the user and the manufacturer.Selection of the product level depends on the product standard.

6 Comment on the standards

At present, there are many standards mentioning the situation of using 1.2/50μs lighting to do the test, but the different standard has different test objective. For example, high-pressure test also mentioned the lighting test for the impulse withstand voltage test with the high-pressure and high-resistance generator. At this moment, although the voltage of the generator is high, the energy is not huge. This kind of test is conducted in the off-line state of the equipment. On the contrary, IEC 61000-4-5 standard requires conducting the surge anti-interference measurement. Due to the low circuit impedance, the output impedance of the generator is also required to be low. In this way, the generator suitable for surge anti-interference measurement not only needs to have high output voltage, but also needs to have low output impedance and large energy output characteristics. Since the equipment conducts the measurement in the on-line state, coupling and decoupling network should be used. It can be seen that the above mentioned two kinds of experiments are totally different, which should not be confused.

Lisun Instruments Limited was found by LISUN GROUP in 2003.LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer Integrating Sphere System, LED Test Instruments, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test ,Dustproof Test , High and Low temperature Humidity Chamber, Plug and Switch Testing,etc.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Friday, February 21, 2020

How to Use TM-21 to Estimate LED Luminaries Life?

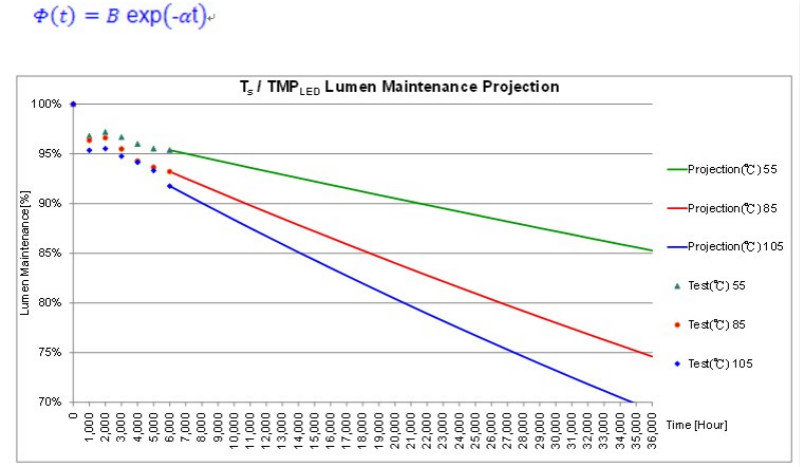

LED has the features of long time. According to different power drivers and use conditions, the life of LED can be up to 50,000 hours pr more. LED will not extinguish directly like other light source but decay gradually. Therefore, luminous decay will lead to output low light after long time use, which will make products not meet requirements. And how to use TM-21 to estimate LED luminaries life?

In order that LED industry persons have a clear concept of TM-21 and learn how to use TM-21 to estimate LED products. We will make 4 programs to explain the application and prediction method of LM-80-08 and TM-21-11:

Step 1: LED components manufacturers do at least 6,000 hours test at 3 temperatures (55C°/85 C°/Optional Temperature) for LED Source (Package/Array/Module) according to LM-80-08.

Required samples number: (Related to the prediction time)

Test Time Requirement (Related to Prediction Accuracy)

At least 6,000 Hours, recommend 10,000 Hours, you should obtain the LED light attenuation information every 1,000 hours, interval time is shorter(such as 500 hours), which can improve the accuracy of the prediction time.

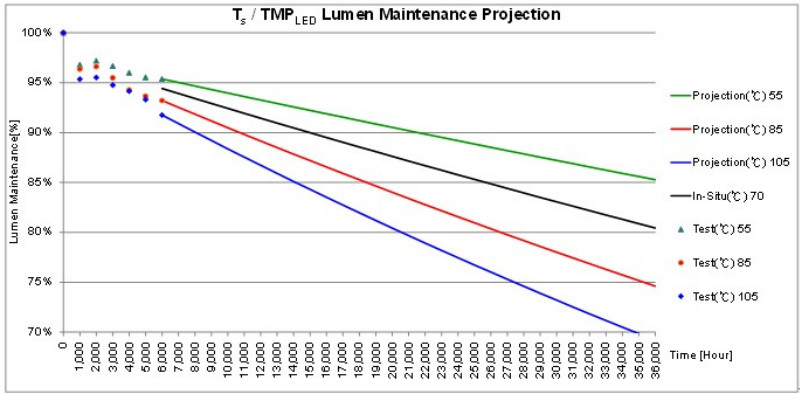

Step 2: Predict 3 test temperatures (55C°/85 C°/Optional Temperature) long life information according to TM-21-11.

Obtain the average value of experiment data at each temperature, the time rules to take test information as follow:

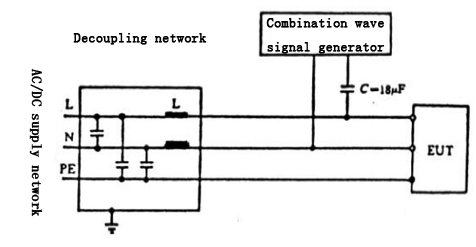

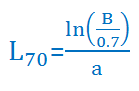

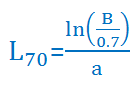

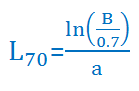

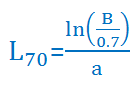

According to formula, calculate the 70% lumen maintenance life time value at every temperature experiment under ENERGY STAR standard.y=mx+b, B=exp(b), a=-mUse Exponential Least Squares Curve-Fit to get Slope m and Intercept b, when calculate m and b, the interval is denser if test time is longer, its accuracy will increase and then calculate the value of B and α.

L70: Time to 70% lumen maintenance

Use sample number in Step 1 to predict multiple times standard to judge:

(6K) : LM-80 Test Time; (6K)=6,000 Hours; (10K)=10,000 HoursRepresentation: L70(6K) = XX,XXX hours

XX,XXX Hours : Sample≧20ea, Test Time=6,000, Predict 6 times to 36,000 hours

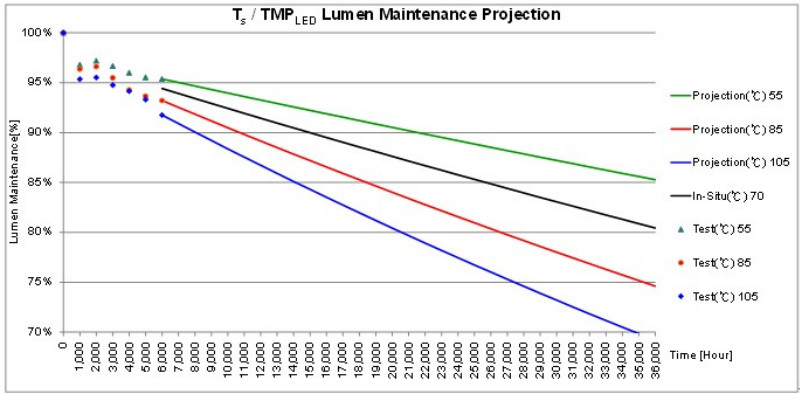

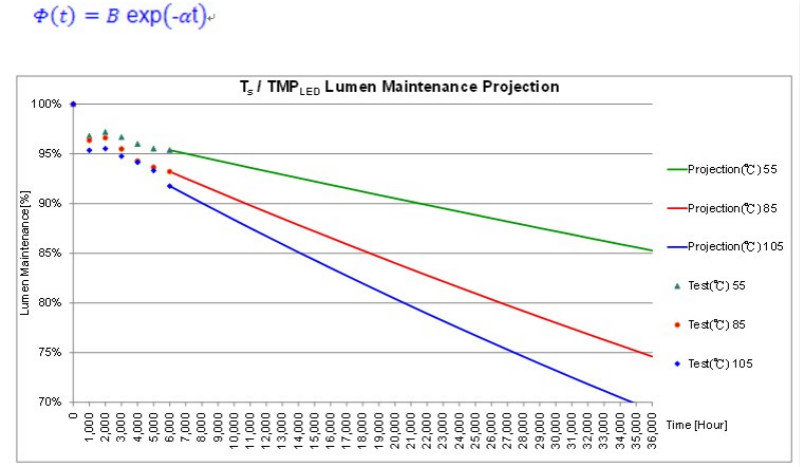

Use Exponential Formation to calculate the lumen maintenance of every time, and then draw the prediction life curve at every test temperature according to the calculated data.

Step 3: Obtain In Situ Temperature of this LED devise in LED luminaries.

Please refer to ISTMT(In Situ Temperature Measurement Test) formula to obtain the temperature of LED device in LED lumunaries, this test temperature position must be same with Ts set position of LM-80-08, the temperature data taken out is called TMPLED(LED Temperature Measurement Point).

Step 4: Use the calculation results of TMPLED and TM-21 to do Interpolation calculation, to obtain the estimated life value of TMPLED.

Select two close-in temperature points cladding in TMPLED from 3 test temperature points as calculation datum point.

Calculate Arrhenius Model temperature acceleration parameter A and get Decay Rate: α and Fixed value parameter B0.

Use upper formula to calculate the L70 value of TMPLED, same formula represents the result of TMPLED.

L70(6K) > XX,XXX hours

Set into relevant time value and draw the life time prediction curve of TMPLED and 3 Ts.

Lisun LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to IES-LM-80 standards. This system combines Arrhenius Model, which can make users predict L30 and L70 etc lumen maintenance by software after hundreds to thousands of hours test.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

In order that LED industry persons have a clear concept of TM-21 and learn how to use TM-21 to estimate LED products. We will make 4 programs to explain the application and prediction method of LM-80-08 and TM-21-11:

Step 1: LED components manufacturers do at least 6,000 hours test at 3 temperatures (55C°/85 C°/Optional Temperature) for LED Source (Package/Array/Module) according to LM-80-08.

Required samples number: (Related to the prediction time)

| Samples for eachTs | Luminaires V1.1 | LED Lamps V1.4 |

| LED Package | ≥20 | ≥25 |

| LED Mpdul / Array | ≥10 | ≥10 |

Test Time Requirement (Related to Prediction Accuracy)

At least 6,000 Hours, recommend 10,000 Hours, you should obtain the LED light attenuation information every 1,000 hours, interval time is shorter(such as 500 hours), which can improve the accuracy of the prediction time.

Step 2: Predict 3 test temperatures (55C°/85 C°/Optional Temperature) long life information according to TM-21-11.

Obtain the average value of experiment data at each temperature, the time rules to take test information as follow:

| D Test Time (Hour) | Take out the data principle |

| 6000~10000 | 1. Take out the last 5,000 hours to calculate2. 0~1,000 hours data do not use(LED Unstable Period) |

| >10,000 | 1. Take out last 50% that is D/2~D to calculate |

According to formula, calculate the 70% lumen maintenance life time value at every temperature experiment under ENERGY STAR standard.y=mx+b, B=exp(b), a=-mUse Exponential Least Squares Curve-Fit to get Slope m and Intercept b, when calculate m and b, the interval is denser if test time is longer, its accuracy will increase and then calculate the value of B and α.

L70: Time to 70% lumen maintenance

Use sample number in Step 1 to predict multiple times standard to judge:

| Sample Number (Per Temperature) | TM-21 Prediction Multiple Time |

| ≥20ea | 6 times of the test time |

| ≥10ea,<20ea | 5.5 times of the test time |

| <10ea | Not applicable for TM-21 |

(6K) : LM-80 Test Time; (6K)=6,000 Hours; (10K)=10,000 HoursRepresentation: L70(6K) = XX,XXX hours

XX,XXX Hours : Sample≧20ea, Test Time=6,000, Predict 6 times to 36,000 hours

Use Exponential Formation to calculate the lumen maintenance of every time, and then draw the prediction life curve at every test temperature according to the calculated data.

Step 3: Obtain In Situ Temperature of this LED devise in LED luminaries.

Please refer to ISTMT(In Situ Temperature Measurement Test) formula to obtain the temperature of LED device in LED lumunaries, this test temperature position must be same with Ts set position of LM-80-08, the temperature data taken out is called TMPLED(LED Temperature Measurement Point).

Step 4: Use the calculation results of TMPLED and TM-21 to do Interpolation calculation, to obtain the estimated life value of TMPLED.

Select two close-in temperature points cladding in TMPLED from 3 test temperature points as calculation datum point.

Calculate Arrhenius Model temperature acceleration parameter A and get Decay Rate: α and Fixed value parameter B0.

Use upper formula to calculate the L70 value of TMPLED, same formula represents the result of TMPLED.

L70(6K) > XX,XXX hours

Set into relevant time value and draw the life time prediction curve of TMPLED and 3 Ts.

Lisun LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to IES-LM-80 standards. This system combines Arrhenius Model, which can make users predict L30 and L70 etc lumen maintenance by software after hundreds to thousands of hours test.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Surge generator: IEC 61000-4-5-2014 Surge Immunity Test

The International Electrotechnical Commission (IEC) has published IEC 61000-4-5:2014, “Electromagnetic Compatibility (EMC) – Part 4-5: Testing and Measurement Techniques – Surge Immunity Test.”

“IEC 61000-4-5:2014 relates to the immunity requirements, test methods and range of recommended test levels for equipment with regard to unidirectional surges caused by over-voltages from switching and lightning transients. Several test levels are defined which relate to different environment and installation conditions. These requirements are developed for and are applicable to electrical and electronic equipment. The object of this standard is to establish a common reference for evaluating the immunity of electrical and electronic equipment when subjected to surges.”

“The test method documented describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon. This standard defines a range of:

“This third edition cancels and replaces the second edition published in 2005, and constitutes a technical revision which includes the following significant technical changes with respect to the previous edition:

LISUN SG61000-5 Surge Generator is exactly according to the latest version of this IEC standard. SG61000-5_Surge Generator

SG61000-5_Surge Generator

Lisun Instruments Limited was found by LISUN GROUP in 2003.LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer Integrating Sphere System, LED Test Instruments, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test ,Dustproof Test , High and Low temperature Humidity Chamber, Plug and Switch Testing,etc.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

“IEC 61000-4-5:2014 relates to the immunity requirements, test methods and range of recommended test levels for equipment with regard to unidirectional surges caused by over-voltages from switching and lightning transients. Several test levels are defined which relate to different environment and installation conditions. These requirements are developed for and are applicable to electrical and electronic equipment. The object of this standard is to establish a common reference for evaluating the immunity of electrical and electronic equipment when subjected to surges.”

“The test method documented describes a consistent method to assess the immunity of an equipment or system against a defined phenomenon. This standard defines a range of:

- test levels;

- test equipment;

- test setups;

- test procedures.”

“This third edition cancels and replaces the second edition published in 2005, and constitutes a technical revision which includes the following significant technical changes with respect to the previous edition:

- a new Annex E on mathematical modelling of surge waveforms;

- a new Annex F on measurement uncertainty;

- a new Annex G on method of calibration of impulse measuring systems;

- a new Annex H on coupling/decoupling surges to lines rated above 200 A.”

LISUN SG61000-5 Surge Generator is exactly according to the latest version of this IEC standard.

SG61000-5_Surge Generator

SG61000-5_Surge GeneratorLisun Instruments Limited was found by LISUN GROUP in 2003.LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.