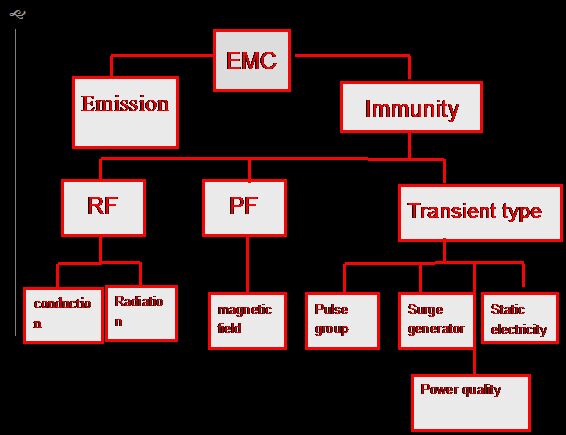

Electromagnetic Compatibility EMC refers to the ability of a device or system to function properly in its electromagnetic environment and does not constitute an electromagnetic disturbance to anything in the environment.

Sensor electromagnetic compatibility refers to the adaptability of the sensor in the electromagnetic environment, maintaining its inherent performance and the ability to perform specified functions. It contains two requirements: on the one hand, the sensor should not cause electromagnetic interference to the environment in the normal operation process, and the sensor must have a certain degree of immunity to the electromagnetic interference in the environment.

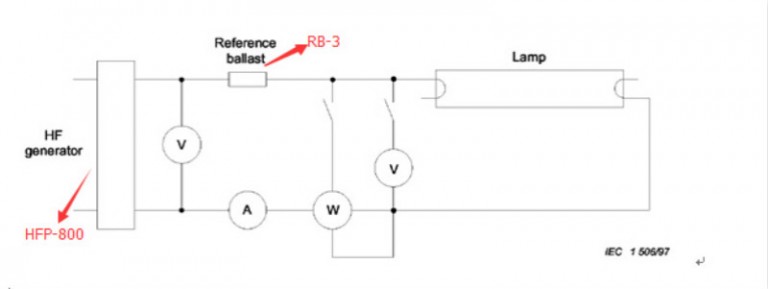

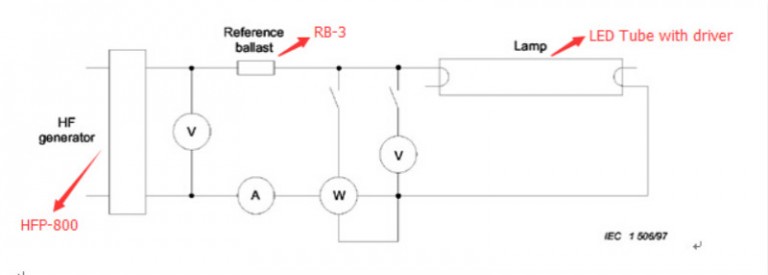

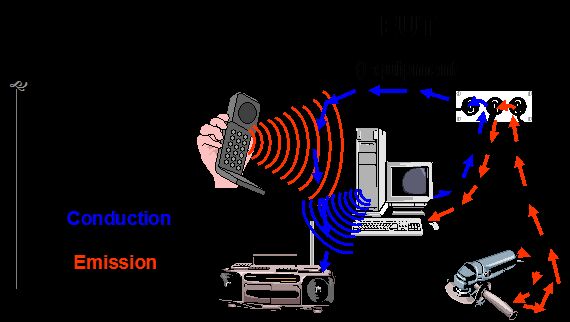

Figure 1: the classification of EMC

Figure 2: The Schematic of EMC

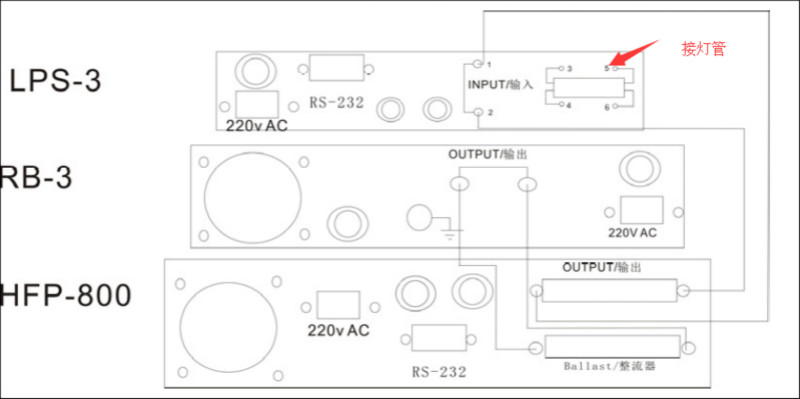

Introduction of products

1. Conducted radiation interference

The RF interference frequency range emitted by this standard covering equipment is 9KHZ-400GHZ. The limits in this standard are determined on a probabilistic basis so that disturbances are suppressed within economically reasonable limits while still achieving adequate levels of radio protection and electromagnetic compatibility. In exceptional cases, additional requirements may be made. The EMI Test System EMI-9KC/EMI-9KB fully meets

CISPRl6-1,

GB17743, FCC,

EN55015 and EN55022.

EMI-9KA/9KB

EMI Receiver System is a main test system for EMI (Electro Magnetic Interference) testing.

2. Static Immunity

The International Electrician Commission (IEC) has issued

IEC 61000-4-2 version 2.0 (2008-12) entitled “

Electromagnetic Compatibility (EMC) – Part 4-2: Test and Measurement Techniques – Electrostatic Discharge Immunity Test”.

This standard covers the immunity requirements and test methods for electrical and electronic equipment subjected to electrostatic discharge, including from equipment to direct operators, from personnel to adjacent objects. In addition, it defines the range of test levels for different environments and different installation conditions, and establishes test procedures. The purpose of this standard is to establish a common and repeatable benchmark for evaluating the performance of electrical and electronic equipment when subjected to electrostatic discharge. It also lists statics that may occur in objects near people and critical equipment, as well as typical waveforms of discharge current, test range, test equipment, test setup, test procedures, calibration procedures, and measurement uncertainty.

The second edition of the standard replaces the first edition published in 1995, and its amendment 1 (1998) and its amendment 2 (2000) together constitute a technical revision that is fully compliant with the basic IEC EMC guidelines 107.

Electrostatic Discharge Simulator (Electrostatic Gun) from LISUN is in full compliance with IEC 61000-4-2,

EN61000-4-2, ISO10605, GB/T17626.2, GB/T17215.301 and GB/T17215.322.

3. RF Radiation Immunity

The international standard IEC61000-4-3 was drafted by the 65A subcommittee of the IEC Technical Committee 65 and replaced IEC801-3 published in 1984.

Electromagnetic radiation affects most electronic devices in some way. In addition to intentional electromagnetic energy, some devices generate stray radiation, such as electric welders, thyristor rectifiers, fluorescent lamps, and the like. This interference is manifested in most cases as conducted interference, which is involved in other standards of this series of standards. Methods to prevent the effects of electromagnetic fields often also reduce the effects of such sources of interference.

SDR-2000B

Magnetic Shielding Chamber for EMI from LISUN is fully compliant with IEC61000-4-3 and has a suitable size to maintain a uniform field with sufficient space relative to the EUT.

4. Electrical Fast Transient Burst Immunity

The international standard

IEC61000-4-4 was developed by the 77B subcommittee of the IEC Technical Committee 77. The purpose of this standard is to evaluate a common reproducible basis for assessing the performance of electrical and electronic equipment’s power supply ports, signals, and control ports in the presence of repetitive fast transients. However, the test of special equipment or systems is not regulated. The repetitive fast transient test is a test that couples a burst of many fast transient pulses to the power ports, signals, and control ports of electrical and electronic equipment. The main points of the test are short rise times of transients, repetition rates and low energy.

EFT61000-4

EFT Immunity Tester from LISUN is developed for the requirements of fast transient burst immunity tests and is the ideal source of interference for EMS measurements.

5. Surge Generator Immunity

The international standard

IEC61000-4-5 was developed by the 65th Subcommittee of the IEC Technical Committee 65. This standard has the status of a basic electromagnetic compatibility publication. The immunity requirements for the unipolar surge caused by the switch and lightning transient overvoltage, the test method and the recommended test level range are specified, and several test levels related to different environments and installation conditions are specified.

Automatic Lightning

Surge Generator (or Lightning Surge Immunity) SG61000-5 is used to assess the power cord and connect the internal switch stood in line to connect the internal switch to provide a common basis for switching the natural world and lightning caused by the high-energy transient interference performance.

6. RF Conducted Immunity

The international standard

IEC61000-4-6 was developed by the 65A subcommittee of the IEC Technical Committee 65 and the 77B subcommittee of the IEC Technical Committee 77. In accordance with IEC Guide 107, it has the status of a basic EMC publication. This standard relates to electrical and electronic equipment requirements for electromagnetic immunity from RF transmitters in the frequency range from 9KHZ to 80MHZ. The device is coupled to the RF field by a cable.

The source of disturbance referred to in this standard usually refers to the electromagnetic field from the RF transmitter. This electromagnetic field may act on the entire cable that connects the mounting equipment. Although the size of the device being harassed is smaller than the wavelength of the disturbance frequency, the output and input lines may become passive receiving antenna networks because their length may be several wavelengths.

The RFCI61000-4-6

RF Conducted Immunity Test System from LISUN is mainly used for conduction sensitivity testing.

7. Power Frequency Magnetic Field Immunity

The international standard

IEC61000-4-8 was developed by the 77B subcommittee of the IEC Technical Committee 77. This standard is the eighth part of the fourth part of IEC61000, which has the status of a basic EMC publication in accordance with the IEC107 guidelines. This standard specifies the immunity requirements of equipment under operating conditions for power frequency magnetic field disturbances in the following locations: residential and commercial areas; industrial and mining areas and power plants; medium voltage and high voltage substations. For equipment installed in different locations, the applicability of this standard is determined by the phenomena indicated in Chapter 3. The purpose of this standard is to establish a common and reproducible benchmark to evaluate the performance of electrical, electronic, and electronic equipment used in power frequency magnetic fields. The power frequency magnetic field is generated by the power frequency current in the conductor, or a very small amount is generated by other devices in the vicinity.

PFM61000-8A

Magnetic Field Generator from LISUN is a high stability energy test equipment mainly used for electronic product design requirements of immune characteristics and normal frequency magnetic field testing requirements.

8. Voltage Drop Immunity

The international standard

IEC/EN61000-4-11 was drafted by the 77B subcommittee of the 177th Technical Committee of the IEC. This standard is Part 11 of Part 4 of IEC61000 and is a basic EMC standard in accordance with IEC Directive 107. This standard specifies the immunity test method and preferred test level range for voltage sag, short interruption and voltage change of electrical and electronic equipment connected to the low voltage power supply network. This standard applies to electrical and electronic equipment with a rated input current of no more than 16A per phase. The purpose of this standard is to establish a general guideline for evaluating the immunity of electrical and electronic equipment to voltage dips, short interruptions and voltage changes.

CSS61000-11

Voltage Dip and Interruptions Generator from LISUN is a highly reliable device specially designed for the characteristics and requirements of voltage dip and short-term interrupt immunity test.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are

Goniophotometer,

Spectroradiometer,

Integrating Sphere,

LED Test Instruments,

CFL Test Instruments,

Photometer and Colorimeter,

EMC & EMI Testing,

Surge Generator,

Electrical Safety Testing,

Environmental Test Chamber,

Waterproof Test ,

Dustproof Test Chamber,

High and Low temperature Humidity Chamber,

Plug and Switch Testing,

AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep:

Service@Lisungroup.com, Cell/WhatsApp: +8615317907381

Sales Dep:

Sales@Lisungroup.com, Cell/WhatsApp: +8618917996096

SG61000-5_Surge Generator

SG61000-5_Surge Generator

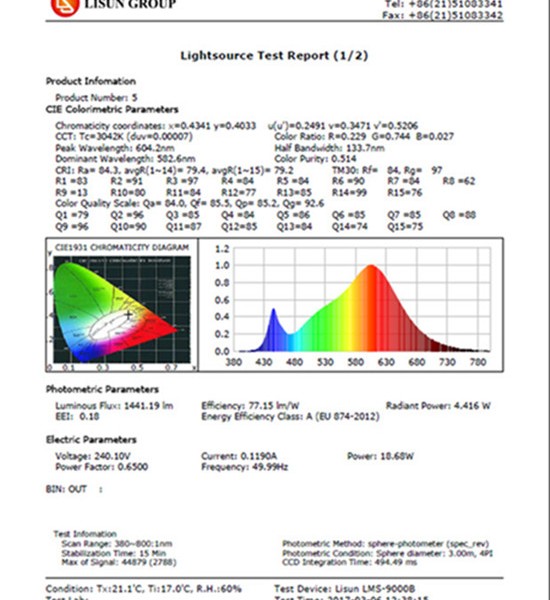

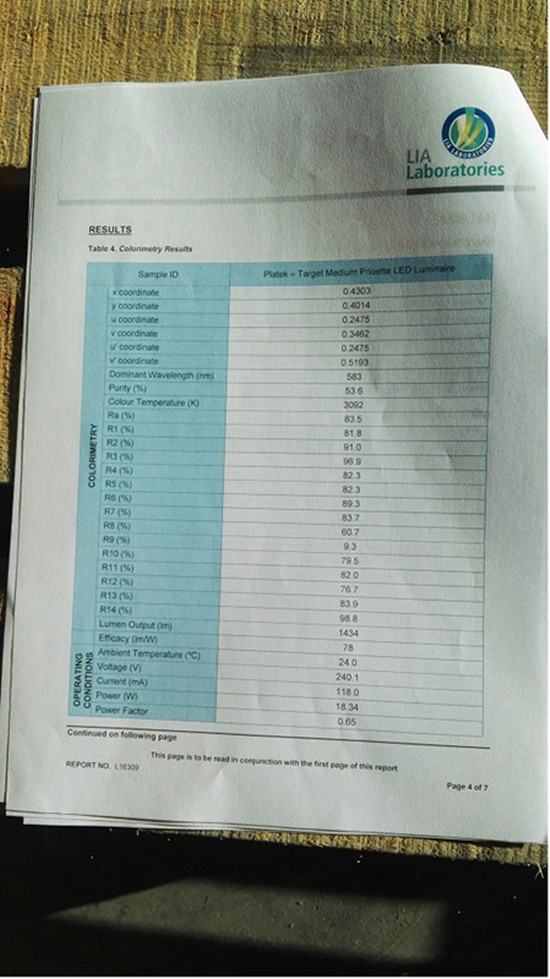

LPCE-3_ CCD Spectroradiometer Integrating Sphere Compact System

LPCE-3_ CCD Spectroradiometer Integrating Sphere Compact System LPCE-3 CCD Spectroradiometer Integrating Sphere Compact System

LPCE-3 CCD Spectroradiometer Integrating Sphere Compact System LPCE-3 CCD Spectroradiometer Integrating Sphere Compact System

LPCE-3 CCD Spectroradiometer Integrating Sphere Compact System